2026 Top Steel Pipe Fittings Types You Need to Know?

In today's industrial landscape, the demand for steel pipe fittings is steadily rising. According to a recent market report, the global steel pipe fittings market is projected to reach $10 billion by 2026, with a compound annual growth rate (CAGR) of 5%. This growth reflects the increasing need for infrastructure development and maintenance across various sectors, including construction, oil and gas, and water management.

Steel pipe fittings are crucial components used to connect sections of piping, allowing for efficient fluid transport. Different types exist, such as elbows, bends, and tees, each serving unique purposes in piping systems. However, selecting the right fittings can be challenging. Engineers face difficulties with compatibility and performance under various conditions. A lack of standardization in fittings sometimes leads to costly rework.

Understanding the various types of steel pipe fittings and their applications is essential for industry professionals. Knowledge of industry standards, such as ASTM and ASME, can help navigate complex decisions. As we explore the top steel pipe fittings for 2026, we aim to shed light on the evolving landscape, offering insights that can help optimize project outcomes.

Types of Steel Pipe Fittings: An Overview of 2026 Trends

When discussing steel pipe fittings, trends in 2026 highlight various types that are shaping the industry.

Welded fittings are gaining traction due to their strength and durability. These fittings are known for their ability to withstand high pressure.

However, they require skilled labor for installation. It’s essential to consider the costs involved.

Another emerging type is threaded fittings. These are appreciated for their ease of use. They allow for quick assembly and disassembly.

Yet, they may not provide the same level of leak protection as welded types. This is important for projects involving fluid transport.

Clarity in specifications is often overlooked but crucial.

In 2026, socket weld fittings are also becoming popular. They offer good performance in high-pressure applications.

However, the installation process can lead to complications if not done correctly. Industry professionals need to be attentive to these details.

Ensuring every fitting is installed properly can prevent future issues.

Key Materials Used in Steel Pipe Fittings Manufacturing

When it comes to manufacturing steel pipe fittings, several key materials play crucial roles. Carbon steel and stainless steel are among the most common materials. Carbon steel provides strength and durability. It’s often favored for its cost-effectiveness. Meanwhile, stainless steel resists corrosion and is used in high-pressure applications. A report by the Global Steel Pipe Fittings Market estimates that the growing demand for these materials will increase by 4.5% annually through 2026.

Another material gaining attention is alloy steel. This type combines elements to enhance properties like toughness and hardness. It is ideal for extreme conditions. Additionally, plastic-coated fittings are increasingly used. They offer added protection against corrosion. This can prolong the lifespan of fittings, especially in harsh environments.

Tips: Always evaluate the environment where fittings will be used. You may find that alloy steel performs better in extreme conditions. Regular maintenance checks are essential. They can help detect deterioration early, ensuring system integrity. Keep in mind that material choice directly impacts the overall performance of your piping system. Make informed decisions to avoid costly replacements.

2026 Top Steel Pipe Fittings Types You Need to Know

This bar chart represents the estimated percentage of various types of steel pipe fittings used in manufacturing processes in 2026. The data reflects trends based on materials commonly used in the industry.

Popular Connection Methods for Steel Pipe Fittings

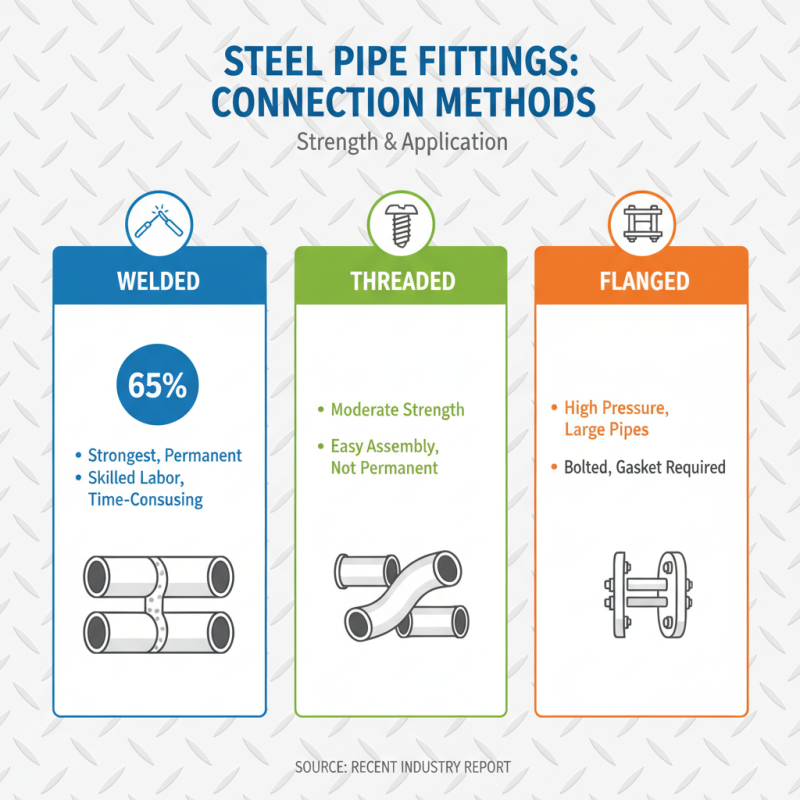

When discussing steel pipe fittings, the connection methods play a crucial role. The most common connections include welding, threading, and flanging. Each method has its own strengths and weaknesses. According to a recent industry report, about 65% of steel pipe fittings use welded connections due to their strong and permanent nature. However, welding requires skilled labor and can be time-consuming.

Threaded joints are another popular option. They allow for easy assembly and disassembly, which is beneficial for maintenance. Yet, reports indicate that threaded connections may be prone to leaks, especially in high-pressure systems. In fact, leaks in threaded joints account for roughly 30% of failures in piping systems, emphasizing the importance of proper installation.

Flanging is often used for large-diameter pipes, providing a secure connection. However, this method can be expensive due to the additional components required. The choice of connection method impacts overall system efficiency. Each has benefits but also presents challenges. Understanding these nuances is essential for optimizing performance and ensuring reliability in various applications.

Applications and Industries Utilizing Steel Pipe Fittings

Steel pipe fittings play a crucial role in various industries. They connect pipes and facilitate the flow of liquids and gases. Their reliability affects the overall efficiency of systems. In construction, for instance, steel fittings are fundamental in plumbing and HVAC systems. They ensure proper distribution of water, heating, and air. The strength of steel makes it ideal for heavy-duty applications.

In the oil and gas sector, steel pipe fittings are essential. They withstand pressure and corrosive environments. Fittings like elbows and tees help in directing flow. However, installation can be challenging. Misaligned connections can lead to leaks, costly repairs, and environmental hazards. Precise measurement and skilled labor are needed.

Manufacturing industries also benefit greatly from steel fittings. They are used in machinery and assembly lines. These industries require durability and safety. Lapses in quality can lead to serious consequences. It’s vital to choose the right type of fitting for specific applications. Each industry has unique requirements, and understanding these is crucial.

2026 Top Steel Pipe Fittings Types You Need to Know

| Fitting Type | Description | Common Applications | Industries |

|---|---|---|---|

| Elbow | Used to change the direction of the pipeline. | Oil and Gas, Water Supply | Construction, Energy |

| Tee | Allows branching out from one pipeline to another. | Water Distribution, HVAC | Building Services, Manufacturing |

| Reducer | Connects pipes of different diameters. | Chemical Processing, Oil Refineries | Petrochemical, Utilities |

| Coupling | Joins two pipes together. | Water Supply, HVAC Systems | Construction, Industrial |

| Cap | Closes the end of a pipe. | Water Supply, Gas Systems | Energy, Infrastructure |

Future Innovations in Steel Pipe Fitting Designs and Technologies

The future of steel pipe fitting designs and technologies is evolving rapidly. Innovations aim for enhanced durability and efficiency. According to a report from Global Market Insights, the steel pipe fittings market is projected to exceed $50 billion by 2026. This growth is driven by advancements in materials and production techniques.

One key innovation is the development of corrosion-resistant coatings. These coatings significantly extend the lifespan of fittings, reducing maintenance costs. Another trend is the integration of smart technology in fittings. Sensors can monitor pressure and temperature, providing real-time data. This technology is becoming crucial in industries like oil and gas, where safety is paramount.

Tips: Consider the environmental impact. Sustainable materials are gaining traction. Reducing waste during production is essential. Remember, not all innovations are perfect. Some new designs may face unforeseen challenges. Balancing innovation with practical application is vital for success.

Related Posts

-

Top Benefits of Using Carbon Steel Pipe in Construction and Industry

-

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

-

Top SS Pipe Fittings Guide for Ultimate Performance and Durability

-

2026 Best Stainless Steel Pipe Options for Your Projects?

-

How to Choose the Right Pipe Flange for Your Project?

-

Top Stainless Fittings Types for Your Next Project?

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil