Top 10 Tips for Working with 2205 Duplex Stainless Steel Applications

When it comes to materials engineering, 2205 duplex stainless steel stands out for its remarkable combination of strength, corrosion resistance, and versatility. This unique alloy, consisting of approximately equal parts of austenitic and ferritic phases, provides superior mechanical properties that make it an ideal choice for a wide range of industrial applications. From chemical processing plants to oil and gas exploration, understanding the intricacies of working with 2205 duplex stainless steel is crucial for maximizing its performance and longevity.

In this guide, we will delve into the top 10 practical tips for effectively utilizing 2205 duplex stainless steel in various projects. Whether you are involved in design, fabrication, or maintenance, these insights will enhance your capability to work with this exceptional material. By focusing on critical factors such as welding techniques, mechanical properties, and corrosion management, this article aims to equip professionals with the knowledge necessary to achieve optimal results in their applications. The following tips serve as essential guidelines for harnessing the full potential of 2205 duplex stainless steel, ensuring reliability and efficiency in your operations.

Understanding 2205 Duplex Stainless Steel: Properties and Uses

2205 duplex stainless steel is a highly versatile material known for its unique combination of properties. It features a dual-phase microstructure that consists of approximately 22% chromium and 5% nickel, which contributes to its exceptional strength and corrosion resistance. This alloy is particularly resistant to stress corrosion cracking and pitting, making it an ideal choice for applications in harsh environments such as oil and gas, chemical processing, and marine industries. Its mechanical properties allow it to perform well under extreme conditions, ensuring durability and longevity.

In addition to its strength and resistance to corrosion, 2205 duplex stainless steel offers good weldability and formability, which are essential for manufacturing processes. It can be easily fabricated into various shapes and sizes, making it suitable for a wide range of applications, from piping systems to structural components. The material's high tensile strength also means that thinner sections can be used, which can reduce the overall weight of components without compromising performance. These attributes make 2205 duplex stainless steel a popular choice in sectors that demand both strength and resistance to corrosive environments.

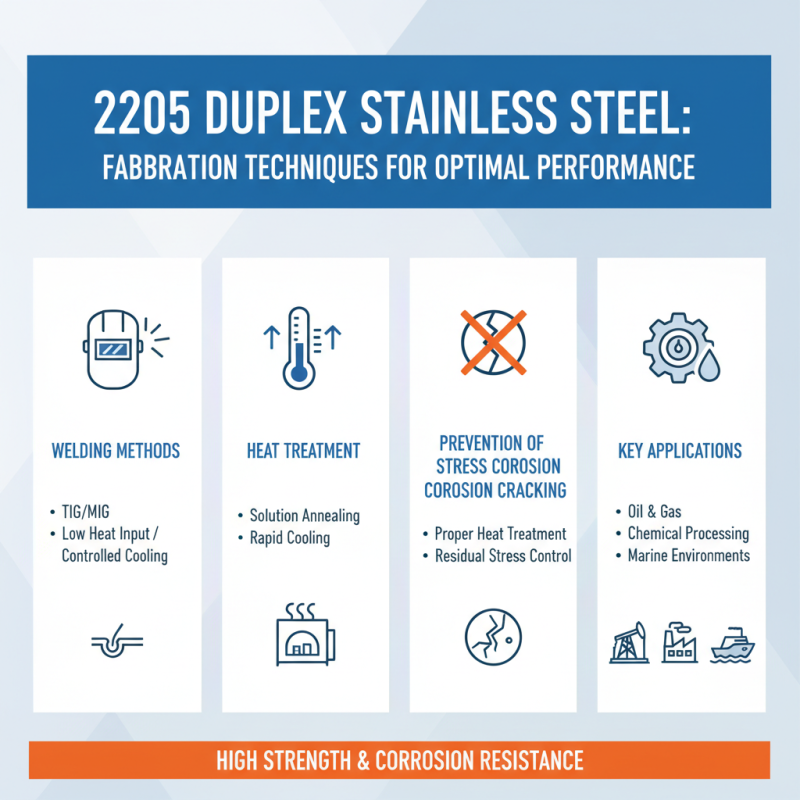

Key Considerations for Fabrication Techniques of 2205 Duplex Steel

When working with 2205 duplex stainless steel, understanding the unique fabrication techniques is vital to ensuring optimal performance in various applications. This material, known for its high strength and excellent corrosion resistance, is increasingly utilized in sectors such as oil and gas, chemical processing, and marine environments. To maximize its properties, professionals must consider factors such as welding methods, heat treatment, and the prevention of stress corrosion cracking.

Welding 2205 duplex steel requires specific techniques to maintain its advantageous microstructure. It is recommended to use nominally low heat input processes, which help in controlling the risk of overheating and subsequent degradation of properties. According to a study published by the International Journal of Advanced Manufacturing Technology, maintaining interpass temperatures below 150°C is crucial to avoid phase transformation. Furthermore, the use of filler materials that match the duplex composition is essential to ensure compatibility and achieve the desired mechanical properties post-welding.

Heat treatment also plays a critical role in enhancing the performance of 2205 duplex stainless steel. Solutions normalized at 1020°C to 1100°C and water quenched can achieve optimal levels of austenite and ferrite balance. Reports from the ASTM indicate that this process can improve the pitting resistance equivalent number (PREN) significantly, making 2205 steel suitable for environments containing chlorides. Additionally, careful attention must be paid to cold working processes, as they can influence the material's mechanical properties and corrosion resistance.

Best Practices for Welding 2205 Duplex Stainless Steel Safely

Welding 2205 duplex stainless steel requires a meticulous approach that considers both its mechanical properties and corrosion resistance. According to a report by the International Stainless Steel Forum (ISSF), duplex stainless steels like 2205 offer a unique combination of strength and corrosion resistance, making them highly desirable for various applications, particularly in the oil and gas industries. However, achieving a successful weld is crucial to harnessing these benefits. The lower thermal expansion rate of duplex stainless steel compared to traditional austenitic steels demands precise control over heat input during welding to avoid issues such as distortion and reduced corrosion resistance.

Best practices for welding 2205 start with the selection of appropriate filler materials. The American Welding Society (AWS) recommends using a filler metal that is compatible with 2205 to maintain its dual-phase microstructure throughout the welded joint. Preheating may not be necessary for this grade, but attention should be given to interpass temperatures, which should not exceed 300°F to minimize the risk of phase imbalance. Additionally, post-weld heat treatment could be beneficial, but it should be approached with caution as it can lead to a reduction in the stainless steel's mechanical properties. Proper shielding gas mixtures, usually a blend of argon and nitrogen, are also critical in preventing oxidation and ensuring a clean, high-quality bead.

Corrosion Resistance in 2205: Enhancing Durability in Applications

Duplex stainless steel 2205 is known for its exceptional corrosion resistance, making it a preferred choice in various demanding applications, including petrochemical plants and marine environments. According to a report by the International Stainless Steel Forum, the use of duplex stainless steels like 2205 can reduce the risk of corrosion-related failures by up to 50% compared to conventional austenitic stainless steels. This remarkable property stems from its unique microstructure, which combines roughly equal parts of austenite and ferrite, leading to a high resistance to pitting and stress corrosion cracking.

In the context of enhancing durability, 2205 exhibits superior resistance to localized corrosion, an issue that can significantly impact the longevity of equipment and structures. A study published by the American Institute of Steel Construction indicated that applications exposed to chlorides, such as marine environments, show increased performance benefits when using 2205, demonstrating over 60% improved resistance to pitting corrosion compared to lower alloy grades. This makes it particularly advantageous for manufacturers and engineers looking to reduce maintenance costs and extend the lifespan of their products in corrosive environments. Additionally, its high strength allows for the design of thinner structures without compromising durability, further optimizing material usage.

Maintenance Tips for Extending the Life of 2205 Duplex Steel Structures

When it comes to extending the life of 2205 duplex stainless steel structures, maintenance plays a crucial role. This material is known for its excellent corrosion resistance and strength, but, like all materials, it requires regular upkeep to ensure its longevity. According to a report by the International Stainless Steel Forum, proper maintenance can increase the service life of duplex stainless steel by 30% or more, especially in harsh environments.

One key maintenance tip is to perform regular inspections of the stainless steel surfaces. Look for signs of corrosion or pitting, as early detection can prevent more significant damage. Cleaning the surfaces periodically with suitable cleaning agents—not abrasive materials—can help remove contaminants that may lead to corrosion. Ensure that water drainage systems are functioning correctly to avoid water pooling, which can accelerate corrosion processes.

Another important aspect of maintenance is the application of protective coatings when necessary. Applying a specialized sealant can provide an added layer of defense against corrosion, especially in environments where there are high levels of chlorides. Additionally, ensuring that joints and welds are adequately protected can vastly reduce the risk of localized failures, as detailed in a study by the American Society of Materials. By following these maintenance tips consistently, you can significantly enhance the durability of 2205 duplex stainless steel applications.

Related Posts

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

-

2025 Top Duplex Stainless Steel Innovations for Enhanced Performance and Durability

-

How to Choose the Right Stainless Steel Tube for Your Project Needs

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil