10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

When embarking on a construction or fabrication project, the choice of materials can significantly impact both the efficiency and durability of the outcome. One crucial material that enters the decision-making process is the mild steel pipe. Experts in the field emphasize the importance of selecting the right mild steel pipe to meet project specifications. According to Johnathan Steele, a leading expert in structural materials, "Choosing the correct mild steel pipe can enhance not only the structural integrity of your project but also its cost-effectiveness."

Understanding the various types of mild steel pipes available is essential for making an informed decision. Factors such as size, thickness, and intended use can drastically alter the performance of the pipe within a system. With so many options on the market, it is imperative to consider the unique requirements of your project. By adhering to best practices when selecting a mild steel pipe, professionals can ensure that their projects comply with industry standards while also maximizing efficiency.

In this article, we will explore ten essential tips that will guide you in choosing the right mild steel pipe for your specific needs, ensuring your project is built on a solid foundation.

Understanding Mild Steel Pipe Specifications and Standards

When selecting mild steel pipes for your project, it's crucial to understand the specifications and standards that govern their use. Mild steel pipes are categorized based on their chemical composition, including the percentage of carbon and other alloying elements. Familiarize yourself with the key standards such as ASME B31.3, which outlines the requirements for process piping systems, ensuring that your choice meets industry regulations for safety and performance.

One essential tip is to consider the application of the piping. Different projects may require specific grades and types of mild steel pipes to withstand varying pressures and temperatures. Additionally, always verify that the product certifications comply with relevant industry standards, as this ensures quality and reliability. Look for pipes with recognized markings that indicate conformity with these specifications, as this can influence the longevity and durability of your installation.

Finally, understanding the market trends can help you make informed decisions. The steel pipe industry is evolving, with factors such as tariffs and rising demand shaping the landscape. Keeping abreast of industry insights can aid in selecting the right mild steel pipe that aligns with your project’s budget and timing needs.

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

Evaluating the Different Grades of Mild Steel for Your Needs

When selecting mild steel pipes for your project, it is crucial to evaluate the different grades available. Mild steel generally comes in various grades, each offering unique properties suited for specific applications. According to the American Society for Testing and Materials (ASTM), common grades include ASTM A36 and ASTM A500, with A36 being widely used due to its excellent weldability and versatility in construction. For more demanding environments, ASTM A500 provides additional strength and enhanced structural integrity, making it suitable for heavy-duty applications.

One essential tip is to consider the mechanical properties of each grade, such as yield strength and tensile strength. For instance, ASTM A36 offers a minimum yield strength of 36,000 psi, while ASTM A500 can provide between 46,000 to 50,000 psi depending on the specific type. Understanding these specifications enables you to select a pipe that can withstand the stresses of your particular project.

Additionally, always check for compliance with industry standards, ensuring the mild steel pipes you choose meet any relevant regulations. This not only guarantees quality but also contributes to the safety and longevity of your project. Prioritizing grades with certifications can provide peace of mind and facilitate smoother project execution.

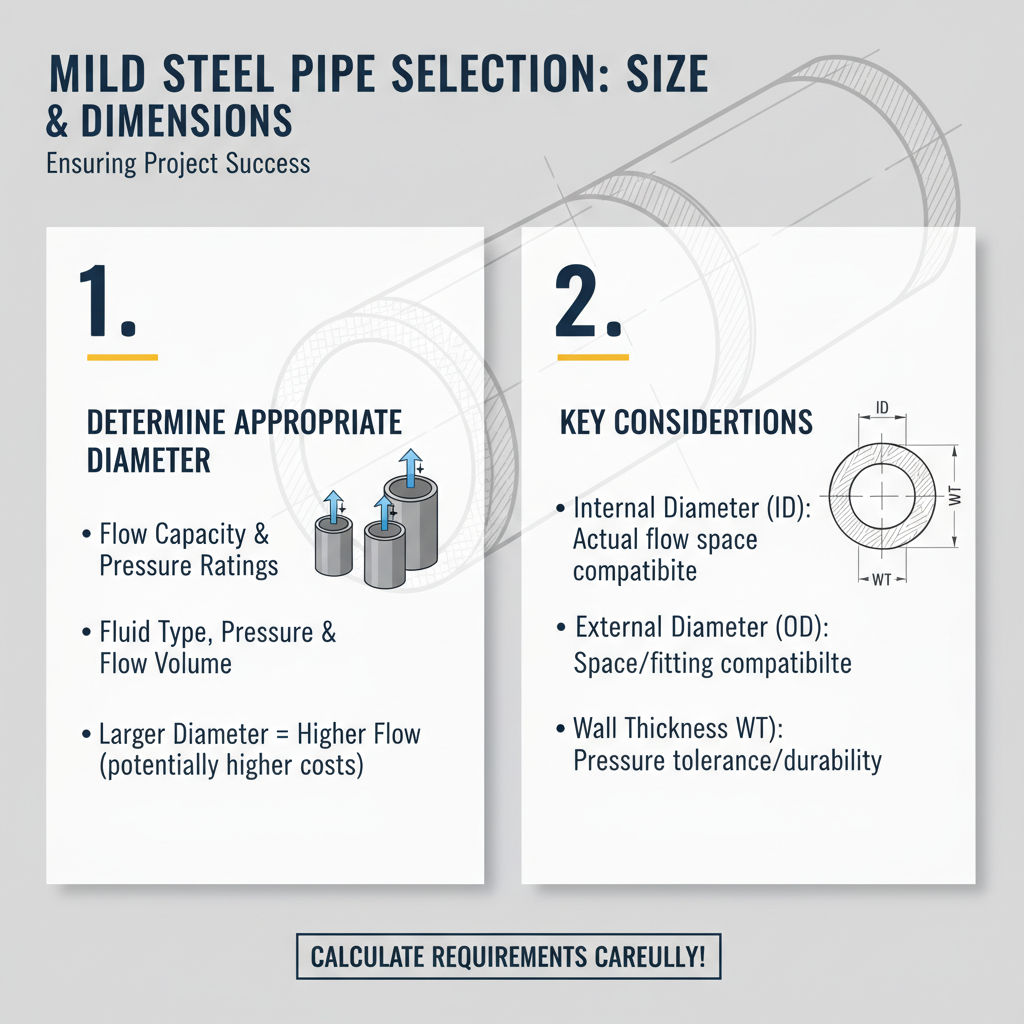

Considerations for Pipe Size and Dimensions in Your Project

When selecting mild steel pipes for your project, understanding pipe size and dimensions is crucial for ensuring the overall success of your application. The first step is to determine the appropriate diameter for your needs. The diameter will significantly affect the flow capacity and pressure ratings of the pipe, making it essential to calculate the requirements based on the fluid type, pressure, and volume of flow. Remember that larger diameters generally enable higher flow rates, but they may also add to costs and installation complexity.

In addition to diameter, the wall thickness of the pipe also plays a vital role in its performance. Thicker walls can handle higher pressures and are less prone to corrosion, but they can also increase the weight and cost of the piping system. It's important to evaluate the trade-offs based on your project's specific requirements. Additionally, adhering to industry standards such as the American National Standards Institute (ANSI) can help ensure that the selected pipe size and dimensions not only fit your project but also comply with safety and regulatory guidelines.

Assessing the Importance of Pipe Coating and Corrosion Resistance

When selecting mild steel pipes for your project, one of the critical aspects to consider is the importance of pipe coating and corrosion resistance. Mild steel is naturally prone to rust and corrosion when exposed to moisture and various environmental conditions. To mitigate this issue, applying protective coatings is essential. These coatings can include options such as galvanization, epoxy, and polyurethane, each offering different levels of protection based on the specific requirements of your project.

Corrosion resistance not only extends the lifetime of the pipes but also enhances their overall performance and safety. By choosing pipes with the appropriate coating, you can significantly reduce maintenance costs and prevent potential failures that could arise from corrosion-related damage. Furthermore, considering the specific environment where the pipes will be installed is crucial. For instance, pipes exposed to high humidity or acidic substances require more robust protective measures to ensure longevity and reliability. Thus, evaluating the corrosion resistance and the type of coating will play a pivotal role in the success of your project.

Cost Analysis: Budgeting for Mild Steel Pipes and Accessories

When budgeting for mild steel pipes and their accessories, it's crucial to understand the factors that will influence your costs. First, conduct a thorough assessment of your project's requirements, including the diameter, length, and intended use of the pipes. These specifications will directly impact the cost, as larger and specialized pipes typically come with a higher price tag. Additionally, consider the quality grade of the mild steel; opting for higher-grade materials may increase initial costs but can lead to significant savings in maintenance and longevity over time.

Another essential aspect of your budget should include the accessories necessary for installation, such as valves, fittings, and supports. These components can vary widely in price depending on their material and design. It's wise to source these accessories from reliable suppliers to avoid unforeseen costs related to poor quality or incompatibility with your pipes. Lastly, don’t forget to factor in labor costs for installation. Whether you plan to hire professionals or tackle the project in-house, understanding the labor requirements will help ensure your budget remains realistic and comprehensive.

Related Posts

-

How to Choose the Right 2205 Duplex Stainless Steel for Your Project Based on Mechanical Properties and Corrosion Resistance

-

2025 How to Choose the Right 304 Stainless Steel Pipe for Your Project

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

2025 Top Duplex Stainless Steel Innovations for Enhanced Performance and Durability

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil