Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

In the realm of plumbing and construction, the importance of steel pipe fittings cannot be overstated. These critical components ensure the integrity and functionality of piping systems, facilitating seamless connections and maintaining pressure across various applications. According to a recent industry report by the American Society of Plumbing Engineers, steel pipe fittings account for approximately 30% of the total materials used in plumbing systems, highlighting their critical role in ensuring system reliability and longevity.

Experts in the field emphasize the necessity of high-quality steel pipe fittings. John Markham, a noted industry expert with over 20 years of experience, asserts, "The durability and strength of steel pipe fittings not only enhance system performance but also ensure safety and compliance with industry standards." This sentiment underscores the fact that investing in superior steel pipe fittings can prevent costly repairs and system failures over time, thereby promoting a more sustainable approach to plumbing projects.

As the construction industry evolves, the demand for efficient and durable plumbing solutions continues to grow. The shift towards sustainable building practices only reinforces the necessity of steel pipe fittings, as they offer a reliable option that can withstand harsh environmental conditions. Understanding their intrinsic value is essential for anyone involved in plumbing projects, ensuring that the systems not only meet current needs but are also prepared for future demands.

The Importance of Steel Pipe Fittings in Plumbing Systems

Steel pipe fittings play a crucial role in plumbing systems, providing the necessary connections and transitions needed for efficient water flow. According to a recent market analysis by Grand View Research, the global plumbing fittings market is expected to reach $80 billion by 2026, highlighting the growing demand for reliable plumbing components. Steel pipe fittings, due to their durability and strength, ensure that plumbing systems can withstand significant pressure and temperature fluctuations, making them ideal for both residential and commercial applications.

In addition to their physical properties, steel pipe fittings contribute to a plumbing system's overall safety and compliance with industry standards. The American Society of Mechanical Engineers (ASME) emphasizes that correctly installed steel fittings can significantly reduce the risk of leaks and failures, which are often caused by inferior alternatives. Furthermore, a report by the National Association of Plumbing-Heating-Cooling Contractors indicates that nearly 40% of plumbing-related failures can be traced back to improper installation or the use of inadequate materials. This data underscores the essential role that high-quality steel pipe fittings play in creating resilient and long-lasting plumbing infrastructures.

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

This bar chart illustrates the importance ratings of various attributes of steel pipe fittings in plumbing projects. The ratings reflect the significance of cost efficiency, durability, corrosion resistance, versatility, and ease of installation, which are crucial for effective plumbing systems.

Types of Steel Pipe Fittings Used in Plumbing Projects

When it comes to plumbing projects, the role of steel pipe fittings cannot be overstated. They serve as crucial connectors, enabling the smooth flow of water and other substances through various plumbing systems. The common types of steel pipe fittings used in these projects include elbows, tees, reducers, and flanges, each serving a distinct purpose in managing fluid dynamics. According to the American Society of Mechanical Engineers (ASME), the choice of fittings can impact the overall efficiency of piping systems, influencing both maintenance costs and system longevity.

Elbows are designed to change the direction of flow, typically at angles of 45 or 90 degrees, allowing for the flexibility needed in complex plumbing layouts. Tees are essential for branching out in different directions, making them ideal for multi-directional systems. Reducing fittings are used to connect pipes of varying diameters, crucial for maintaining pressure and flow rates within a system. Flanges, on the other hand, provide a means for easy connection and disconnection of pipes, simplifying maintenance and repairs. According to a report from the Global Industry Analysts, the steel pipe fittings market is projected to grow significantly, driven by ongoing urbanization and increased investment in infrastructure, showcasing their indispensable role in modern plumbing.

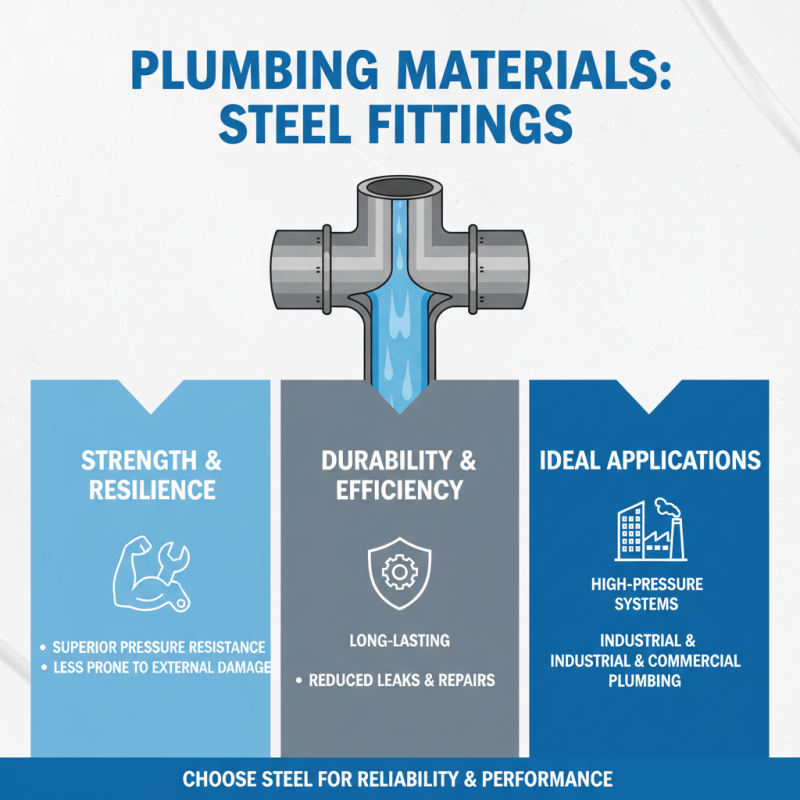

Benefits of Using Steel Pipe Fittings Over Other Materials

When it comes to plumbing projects, choosing the right materials is crucial for durability and efficiency. Steel pipe fittings stand out among various options due to their strength and resilience. Unlike plastic or copper fittings, steel offers superior pressure resistance and is less prone to damage from external forces. This makes steel fittings particularly suitable for high-pressure applications and environments where fittings might be subjected to physical stress.

Another significant benefit of steel pipe fittings is their longevity. Steel’s resistance to corrosion, especially when properly coated or treated, ensures that the fittings maintain their integrity over time. While other materials may degrade or leak due to wear and tear, steel maintains its performance, thereby reducing the need for frequent replacements and repairs. Additionally, steel's ability to handle extreme temperatures makes it an ideal choice for both hot and cold water systems, ensuring consistent performance in varying conditions. These advantages highlight why steel pipe fittings are often the preferred choice for both professional plumbers and DIY enthusiasts alike.

Common Applications of Steel Pipe Fittings in Plumbing

Steel pipe fittings play a crucial role in various plumbing applications, primarily due to their durability and strength. One common application is in the residential plumbing system, where these fittings are utilized to connect pipes of different sizes or to change the direction of water flow. For example, when setting up a network for hot and cold water supply to different fixtures such as sinks and showers, steel fittings ensure a secure and leak-free connection that can withstand high pressure.

In industrial settings, steel pipe fittings are indispensable for transporting liquids and gases under high temperatures and pressures. These fittings are often used in manufacturing facilities for connecting pipes that carry essential materials, such as chemical substances or steam. Their resistance to corrosion and ability to handle thermal expansion make them ideal for applications that involve extreme conditions, ensuring safety and reliability in the plumbing infrastructure.

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects - Common Applications of Steel Pipe Fittings in Plumbing

| Application | Description | Common Fittings Used |

|---|---|---|

| Water Supply | Transporting fresh water into homes and commercial buildings. | Elbows, Tees, Couplings |

| Drainage Systems | Removing wastewater from buildings and ensuring proper drainage. | Wyes, Traps, Cleanouts |

| Heating Systems | Distributing heated water or steam for heating purposes. | Valves, Flanges, Expansion Joints |

| Gas Supply | Transporting natural gas to appliances like heaters and stoves. | Street Elbows, Risers, Adaptors |

| Industrial Applications | Used in various industrial settings for transporting fluids and gases. | Reducers, Crosses, End Caps |

Installation Tips for Steel Pipe Fittings in Plumbing Projects

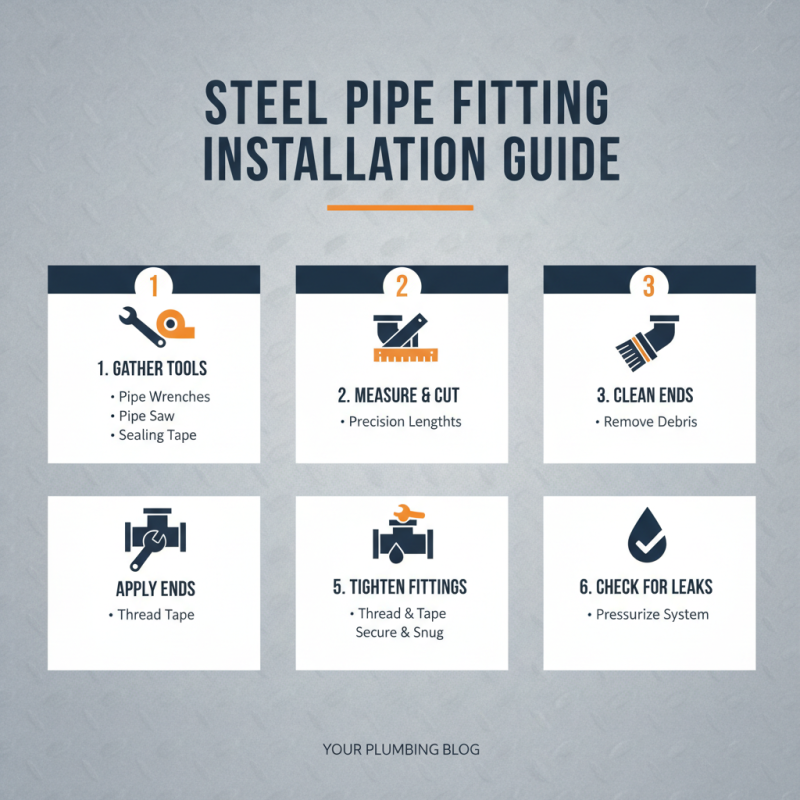

When it comes to plumbing projects, the installation of steel pipe fittings is a crucial step that can significantly impact the overall integrity and functionality of your system. To ensure a successful installation, begin by gathering the necessary tools, including pipe wrenches, a saw for cutting the pipes, and sealing tape for leak prevention. Before you start, it’s essential to measure your pipes accurately and cut them to the required lengths, as precision is key to achieving a tight fit. Properly cleaning the ends of the pipes will help facilitate a better connection and prevent any debris from compromising the seal.

Once your pipes are cut and cleaned, you can begin to assemble the fittings. Apply sealing tape around the threads of the pipes to create a watertight connection, and be sure to follow the manufacturer's guidelines for torque specifications to avoid over-tightening. As you install each fitting, check for misalignments and adjust as necessary to ensure everything is straight and secure. After installation, it's advisable to conduct a pressure test to check for leaks, giving you the peace of mind that your plumbing system will perform reliably for years to come. These installation tips will help you navigate the complexities of working with steel pipe fittings, ultimately contributing to the success of your plumbing projects.

Related Posts

-

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

-

2025 How to Choose the Right 304 Stainless Steel Pipe for Your Project

-

How to Choose the Right Stainless Steel Tube for Your Project Needs

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

-

How to Choose the Right Steel Pipes and Fittings for Your Projects

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil