Top SS Pipe Fittings Guide for Ultimate Performance and Durability

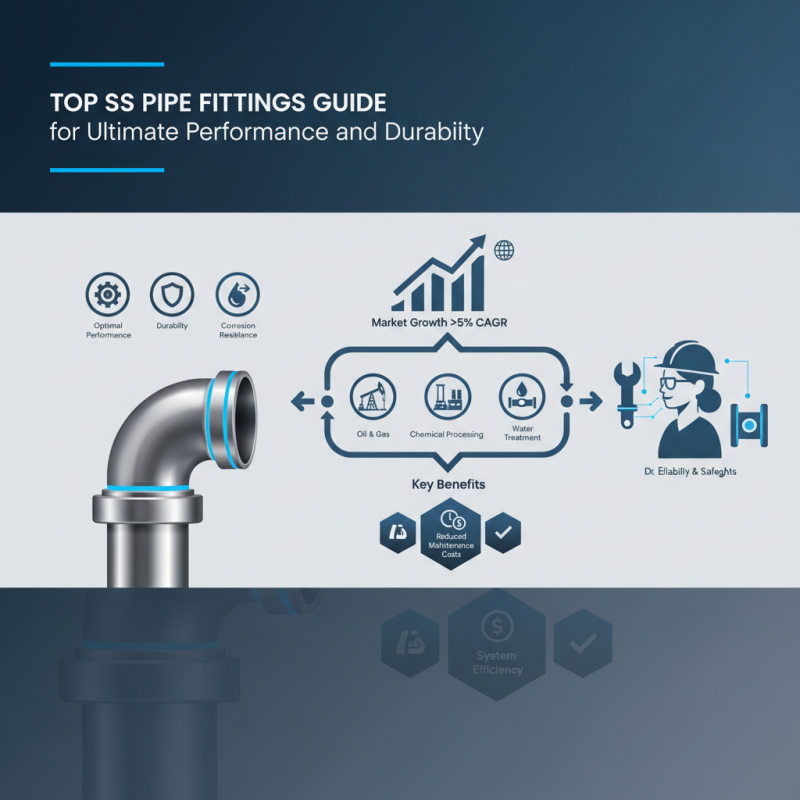

In the realm of industrial plumbing and piping systems, the selection of stainless steel (SS) pipe fittings stands out as a pivotal factor for ensuring optimal performance and longevity. According to a report by the Global Market Insights Group, the demand for SS pipe fittings is projected to grow at a compound annual growth rate of over 5% through the next five years, driven by the increasing need for durable and corrosion-resistant piping solutions in various sectors, including oil and gas, chemical processing, and water treatment.

Industry expert Dr. Emily Richards, a leading authority in materials engineering, emphasizes the significance of high-quality SS pipe fittings, stating, "The reliability of piping systems hinges on the integrity of their fittings; premium SS pipe fittings provide not only strength and durability but also enhance the overall safety of industrial operations." As industries evolve and new challenges arise, understanding the properties and advantages of these fittings becomes essential for engineers and project managers alike.

This guide aims to provide comprehensive insights into the features, applications, and selection criteria of SS pipe fittings, highlighting their critical role in maintaining system efficiency and minimizing maintenance costs. By harnessing the best practices and expert recommendations, stakeholders can make informed decisions that contribute to the ultimate performance and durability of their piping systems.

Understanding Stainless Steel Pipe Fittings: Types and Uses

Stainless steel pipe fittings are essential components used in a variety of industrial, commercial, and residential applications. These fittings are categorized into several types, such as elbows, tees, reducers, and flanges. Each type serves a specific purpose, enabling the efficient flow of fluids and gases within piping systems.

According to a report by the Business Research Company, the global market for stainless steel fittings is projected to reach $4.35 billion by 2026, reflecting the growing demand across various sectors, including construction, automotive, and oil and gas industries.

Understanding the different types of stainless steel pipe fittings and their applications is crucial for ensuring optimal performance and durability. For instance, elbows are used to change the direction of flow, while tees are utilized for branching out configurations. The most commonly used standards for these fittings are ASTM A403 and ASME B16.9, which specify the required mechanical properties and dimensions. Additionally, stainless steel grades like 304 and 316 are widely preferred due to their corrosion resistance and strength, with 316 grade offering enhanced resistance to chloride environments, making it ideal for marine applications.

The choice of fitting type and material directly affects the longevity and reliability of the piping system, emphasizing the need for careful selection based on operational conditions.

Key Factors to Consider When Choosing SS Pipe Fittings

When selecting stainless steel (SS) pipe fittings, several key factors must be evaluated to ensure optimal performance and longevity. The first consideration is the type of stainless steel grade suitable for your application. Common grades include 304 and 316, each possessing unique properties that may benefit specific environments. For instance, grade 316 is more resistant to corrosion and is ideal for marine applications or areas with high chloride exposure, while grade 304 is often sufficient for less aggressive conditions.

Another crucial factor is the fitting design. Different applications may require various fitting types, such as elbows, tees, or reducers. The system's flow requirements and the need for pressure regulation will dictate the appropriate design choice. Additionally, compatibility with the piping system, including its diameter and wall thickness, is essential to ensure a secure fit and to mitigate the risk of leaks. Lastly, it is essential to consider the fittings' finish, as a smooth surface can enhance flow characteristics and reduce the likelihood of corrosion. By diligently evaluating these factors, one can ensure the selection of SS pipe fittings that deliver exceptional durability and reliability in the long run.

Performance Characteristics of Stainless Steel in Pipe Fittings

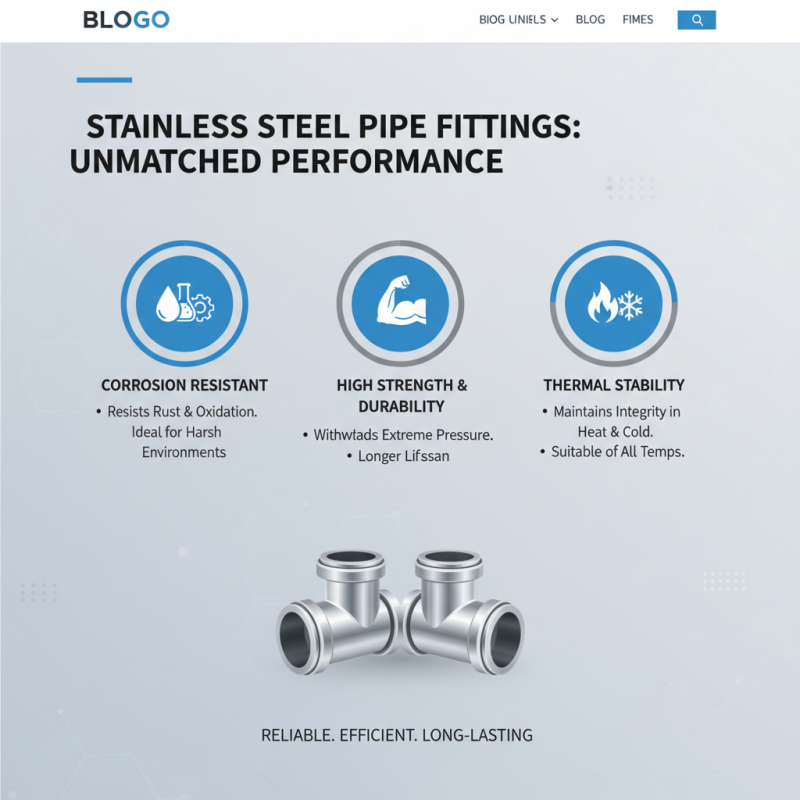

Stainless steel is a preferred material for pipe fittings due to its exceptional performance characteristics and durability. The unique properties of stainless steel, such as corrosion resistance, high strength, and thermal stability, make it an ideal choice for various applications. Its high resistance to oxidation and rust allows it to withstand harsh environments, ensuring a longer lifespan and reducing maintenance costs over time. Additionally, stainless steel fittings can maintain their integrity under extreme temperatures and pressures, making them suitable for both residential and industrial use.

Tips for selecting stainless steel pipe fittings include assessing the specific environmental conditions they will face. Consider the temperature fluctuations and potential exposure to corrosive substances. It is also crucial to choose the right grade of stainless steel; for instance, 304 stainless steel is suitable for most applications, while 316 offers superior corrosion resistance in more aggressive environments. Regular inspections can help identify any early signs of wear or damage, ensuring that the fittings continue to perform optimally.

Another vital aspect is the installation process. Proper installation techniques can significantly impact the performance of stainless steel fittings. Ensure that all connections are tightened according to specifications and that appropriate sealing materials are used to prevent leaks. Regular maintenance checks can enhance the longevity of the system and maintain peak performance throughout its lifecycle.

Durability and Maintenance Tips for SS Pipe Fittings

Stainless steel (SS) pipe fittings are renowned for their strength, durability, and corrosion resistance, making them a preferred choice in countless industries. To ensure optimal performance and longevity, understanding the maintenance requirements of these fittings is essential. According to a report by the American Society of Plumbing Engineers, regular maintenance can extend the service life of SS fittings by up to 30%. Routine inspections for signs of wear, corrosion, and loosening connections are critical in preventing system failures.

Maintenance practices include regular cleaning to remove any build-up of minerals or contaminants that could compromise the integrity of the fittings. It is recommended to use a neutral pH cleaner to avoid damaging the protective layer of the stainless steel. Furthermore, adopting a proactive approach to maintenance, such as replacing seals and gaskets at appropriate intervals, can prevent leaks and ensure a secure system. Data from the Stainless Steel Advisory Service indicates that up to 50% of failures in piping systems can be attributed to neglecting regular maintenance. Thus, implementing strategic maintenance plans not only enhances the durability of SS pipe fittings but also contributes to overall operational efficiency.

Applications of Stainless Steel Pipe Fittings in Various Industries

Stainless steel pipe fittings are essential components in a variety of industries due to their resilience, corrosion resistance, and ability to withstand high temperatures and pressures. In the oil and gas sector, these fittings are paramount for piping systems that transport crude oil, natural gas, and refined products. The use of stainless steel not only ensures safety and reliability in these demanding environments but also extends the lifespan of the infrastructure, reducing the need for frequent replacements.

In addition to the oil and gas industry, stainless steel pipe fittings are widely utilized in the food and beverage sector. Their hygienic properties make them suitable for manufacturing processes where cleanliness is crucial, such as in dairy processing or brewing. The inert nature of stainless steel prevents contamination while also enabling easy cleaning, making it a preferred choice for facilities that require stringent sanitation standards. Furthermore, their durability supports the high-volume demands of modern production lines, ensuring efficiency and productivity are maintained.

Related Posts

-

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

-

How to Choose the Right Steel Pipes and Fittings for Your Projects

-

How to Choose the Right Seamless Steel Pipe for Your Project Needs

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil