Why Hot Rolled Coil is Essential for Construction and Manufacturing Industries

Hot rolled coil is a fundamental material that plays a crucial role in both the construction and manufacturing industries. Its versatility and strength make it an essential choice for a wide range of applications. As construction projects continue to rise globally, the demand for reliable building materials has never been higher. Hot rolled coil, with its unique properties, provides the necessary structural integrity and durability that construction professionals seek when fabricating components such as beams, columns, and reinforcements.

In manufacturing, hot rolled coil serves as a critical input for producing various products, from automotive parts to heavy machinery. The hot rolling process enhances the material’s physical characteristics, allowing for better formability and weldability, which are vital in production scenarios. Furthermore, the ability to create large quantities of hot rolled coil efficiently meets the industry's high demand, ensuring that manufacturers can sustain their operations without compromising quality. As we delve deeper into the significance of hot rolled coil, it's essential to highlight its impact on the advancement of industrial practices and its contribution to the overall growth of the economy.

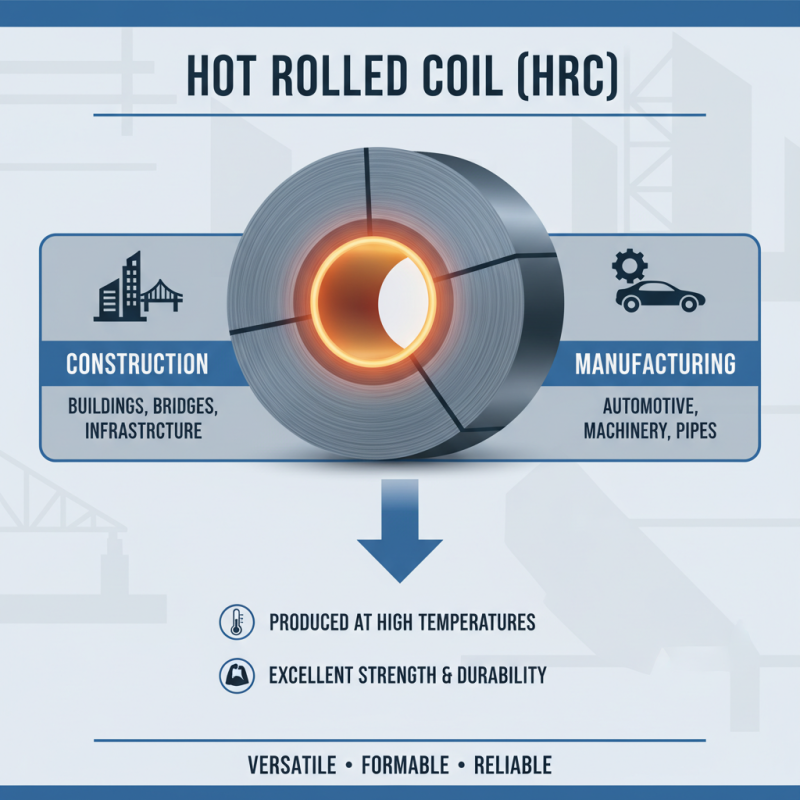

The Importance of Hot Rolled Coil in Construction and Manufacturing

Hot rolled coil (HRC) plays a pivotal role in the construction and manufacturing industries due to its versatility and excellent mechanical properties. This type of steel is produced by rolling steel at high temperatures, which allows it to be easily shaped and formed into a variety of dimensions and thicknesses. Its reliable strength and durability make HRC an essential material for constructing buildings, bridges, and various industrial applications. The physical characteristics of hot rolled coil enable it to resist deformation under stress, making it a preferred option for structural components.

When utilizing hot rolled coil, manufacturers should consider specific tips to ensure optimal outcomes. First, proper handling and storage are crucial to prevent corrosion and damage; using protective coverings can extend its lifespan. Second, understanding the specific grade of hot rolled coil required for a project can significantly influence performance and safety. It is vital to consult with industry experts or material engineers to select an appropriate grade suitable for the intended applications.

Additionally, embracing sustainable practices in sourcing hot rolled coil can enhance environmental responsibility within the industry. By opting for producers that prioritize sustainable manufacturing processes or recycled materials, companies not only reduce their ecological footprint but also align with growing consumer demand for eco-friendly products. This proactive approach supports a more sustainable future while meeting the essential needs of construction and manufacturing sectors.

Key Properties of Hot Rolled Coil and Their Impact on Performance

Hot rolled coil (HRC) is a fundamental material in the construction and manufacturing industries due to its unique properties and versatile applications. One of the key characteristics of HRC is its high strength-to-weight ratio, which allows for the construction of durable structures without excessive material usage. According to a recent report by the World Steel Association, hot rolled steel has not only demonstrated remarkable tensile strength but also excellent ductility, making it an ideal choice for a variety of construction applications including beams, columns, and even metal roofing.

Moreover, hot rolled coils offer exceptional thermal and electrical conductivity, which is crucial in many manufacturing processes. This property enhances the efficiency of manufacturing machinery and reduces energy costs, providing an additional economic benefit. The International Organization for Standardization (ISO) states that the demand for HRC has seen a steady annual growth rate of approximately 3-5%, driven by infrastructure development in emerging markets and increased urbanization. Such data underlines the importance of HRC as a reliable material that supports modern manufacturing needs, ultimately contributing to advancements in both efficiency and sustainability across industries.

Market Trends: Demand for Hot Rolled Coil in the Construction Sector

The demand for hot rolled coil in the construction sector has been steadily increasing, driven by a robust growth in infrastructure projects and urban development. Hot rolled coil, known for its excellent workability and versatility, is used in a wide range of applications, including structural beams, panels, and frames. As economies continue to recover from the impacts of the pandemic, government spending on infrastructure is surging, which in turn fuels the need for high-quality raw materials such as hot rolled coil.

Moreover, the construction industry is experiencing a shift towards more sustainable practices. Hot rolled coil, with its ability to be recycled and repurposed, is gaining traction as builders and manufacturers strive to reduce their carbon footprint. This has led to innovative uses in green building projects, where structural integrity and energy efficiency are paramount. As the demand for hot rolled coil grows, manufacturers are also exploring advancements in production techniques to streamline processes and enhance the material’s properties, ensuring that it meets the evolving needs of the construction sector.

Comparative Analysis: Hot Rolled vs. Cold Rolled Steel in Manufacturing

Hot rolled and cold rolled steel are two primary forms of steel processing that serve distinct purposes in the construction and manufacturing sectors. Hot rolled steel is produced by rolling steel above its recrystallization temperature, which makes it more malleable and easier to work with. This process allows for the creation of larger and thicker steel products, often resulting in lower production costs. The rough, scale-covered finish of hot rolled steel can be advantageous in applications where precise tolerances and surface finish are not critical, making it ideal for structural components, construction beams, and heavy machinery.

In contrast, cold rolled steel undergoes further processing at room temperature. This additional step provides benefits such as tighter tolerances, improved surface finishes, and enhanced mechanical properties. Cold rolled steel is often used in applications where precision and aesthetics matter, such as in automotive parts and appliances. However, the process of cold rolling generally leads to higher production costs and may limit the thickness of the material produced. Ultimately, the choice between hot rolled and cold rolled steel depends on the specific requirements of the project, weighing factors such as budget, desired strength, and surface quality.

Comparison of Hot Rolled and Cold Rolled Steel Usage in Construction and Manufacturing

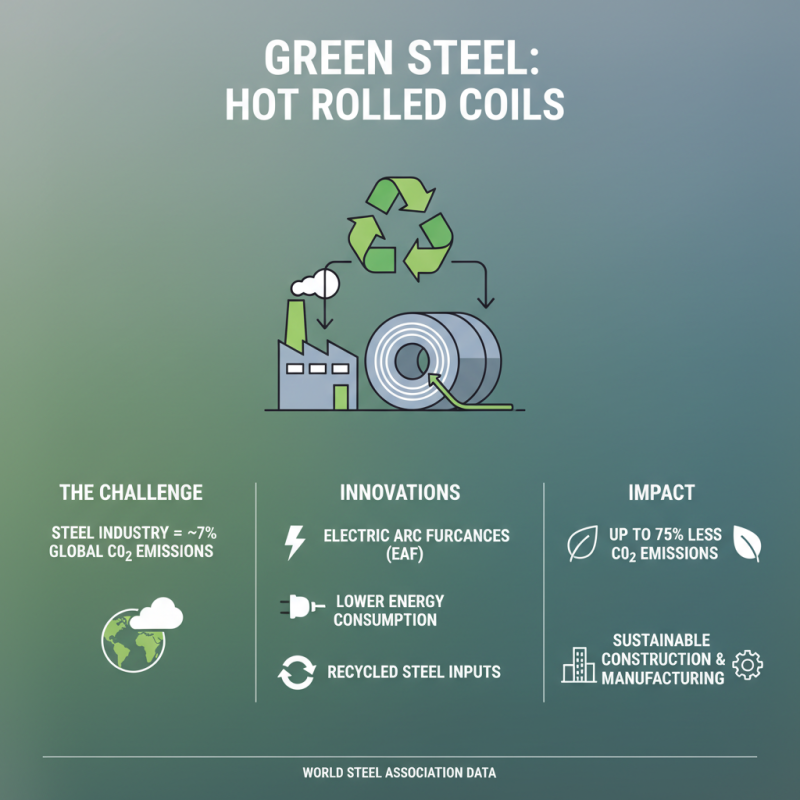

Sustainability Considerations in the Production of Hot Rolled Coils

The production of hot rolled coils (HRC) plays a critical role in the sustainability efforts within the construction and manufacturing sectors. According to the World Steel Association, the steel industry accounts for approximately 7% of global CO2 emissions, making it imperative to adopt more environmentally friendly production methods. Innovations in the hot rolling process, such as the integration of electric arc furnaces, are helping to reduce energy consumption and emissions significantly. Research indicates that using recycled steel as feedstock can lower emissions by up to 75%, demonstrating a clear path toward sustainable production practices.

Moreover, the adoption of circular economy principles in hot rolled coil manufacturing can further enhance sustainability. By recycling and repurposing steel products, the industry can minimize waste and resource extraction. A report by the International Institute of Steel Construction highlights that increasing the recycling rate of steel to 90% could not only decrease landfill dependency but also reduce the environmental footprint of steel production. As construction demands evolve, the use of sustainably produced hot rolled coils will be essential not only for meeting regulatory requirements but also for responding to rising consumer preferences for environmentally responsible products.

Related Posts

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

How to Choose the Right 2205 Duplex Stainless Steel for Your Project Based on Mechanical Properties and Corrosion Resistance

-

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

-

Top 10 Tips for Working with 2205 Duplex Stainless Steel Applications

-

How to Choose the Best 2 Inch Stainless Steel Pipe for Your Project

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil