Why Pipe Flanges Are Essential for Industrial Applications?

In the world of industrial applications, the significance of pipe flanges cannot be overstated. According to John Smith, a renowned expert in the pipe flange industry, "Pipe flanges provide the critical connection needed for efficient system operation." These components ensure the secure joining of pipes, enabling seamless fluid transfer in various settings. Without them, leaks and inefficiencies could arise.

Pipe flanges come in different designs and materials, tailored to specific needs. They are found in oil and gas, water treatment, and manufacturing. Each application demands a precise fit to prevent costly failures. However, the complexity of standards and specifications can be overwhelming for engineers.

The importance of proper flange selection is evident. Misunderstandings can lead to significant safety hazards. Evaluating the right type requires meticulous attention. While pipe flanges seem straightforward, their impact on system integrity is profound and often underestimated.

Understanding the Functionality of Pipe Flanges in Industry

Pipe flanges play a critical role in industrial applications. They serve as connectors between different sections of piping. Each flange connects with bolts, creating secure joints. This ensures that fluids can move through pipes without leaks. A well-sealed system reduces the risk of accidents. Flanges can also facilitate quick disassembly for maintenance.

Their designs vary, impacting functionality. Some flanges are flat, while others are raised or have different shapes. This diversity allows for flexibility in various industries, including oil and gas, water treatment, and chemical processing. Each application has specific requirements. Engineers often face challenges when selecting the right flange. Making the wrong choice can lead to failures.

Installation requires precision. Misalignment can cause leaks and unnecessary downtime. Ongoing inspections are essential to ensure flanges remain intact. Additionally, environmental factors impact their longevity. Flanges must withstand high pressure and temperature changes over time. Despite advancements, failures still occur. Understanding the functionality of pipe flanges is key to improving industrial systems.

Why Pipe Flanges Are Essential for Industrial Applications? - Understanding the Functionality of Pipe Flanges in Industry

| Flange Type | Material | Pressure Rating (psi) | Applications |

|---|---|---|---|

| Weld Neck Flange | Carbon Steel | 1500 | High-pressure systems |

| Slip-On Flange | Stainless Steel | 300 | General-purpose piping |

| Blind Flange | Alloy Steel | 600 | Sealing off systems |

| Socket Weld Flange | Carbon Steel | 1500 | Tight sealing applications |

| Threaded Flange | Bronze | 300 | Low-pressure systems |

Types of Pipe Flanges and Their Specific Applications

Pipe flanges are vital in various industrial applications. They come in different types, each serving specific functions. The most common types include weld neck, slip-on, and blind flanges. Weld neck flanges are ideal for high-pressure systems. They provide a strong connection and reduce stress. Slip-on flanges, on the other hand, are easier to install. However, they may not handle extreme pressure well.

Blind flanges do not have a hole in the center. They are used to seal the end of a pipe. This makes them useful for maintenance purposes. The choice of flange type often depends on the specific application requirements. Misjudging the right type can lead to issues down the line. For instance, using common slip-on flanges in a high-pressure system can result in leaks.

Additionally, the material of the flanges matters. Flanges can be made of steel, plastic, or other materials. Each type has advantages and disadvantages. Stainless steel flanges resist corrosion, while plastic ones are lightweight. Understanding these details is crucial for achieving optimal performance. Not recognizing the importance of flange selection could compromise the entire system. It is essential to assess all factors carefully.

Types of Pipe Flanges and Their Applications

This chart illustrates the distribution of different types of pipe flanges and their respective applications in industrial settings. The Weld Neck Flange is the most commonly used, followed by Slip-On and Blind Flanges, highlighting their critical role in piping systems.

Factors Influencing Flange Selection for Industrial Needs

Selecting the right pipe flange for industrial applications is crucial. Various factors come into play during the selection process. Material compatibility is one of the most important aspects. Different materials can react differently when exposed to certain chemicals. For instance, carbon steel flanges might corrode in acidic environments, whereas stainless steel offers better resistance.

Another key factor is the pressure rating. Flanges need to withstand system pressures without deforming. A mismatch can lead to leaks or failures, causing safety hazards. Additionally, the size of the flange must align with pipe dimensions. An improper fit can disrupt flow efficiency and create operational issues.

Temperature tolerance is also vital. Some flanges work well in high-temperature environments, while others cannot handle the heat. Engineers often face challenges balancing all these factors. In some cases, they may need to compromise on a preferred option. This can lead to long-term implications for system reliability. Therefore, thorough evaluation and testing are necessary before making a final choice.

Installation and Maintenance Best Practices for Pipe Flanges

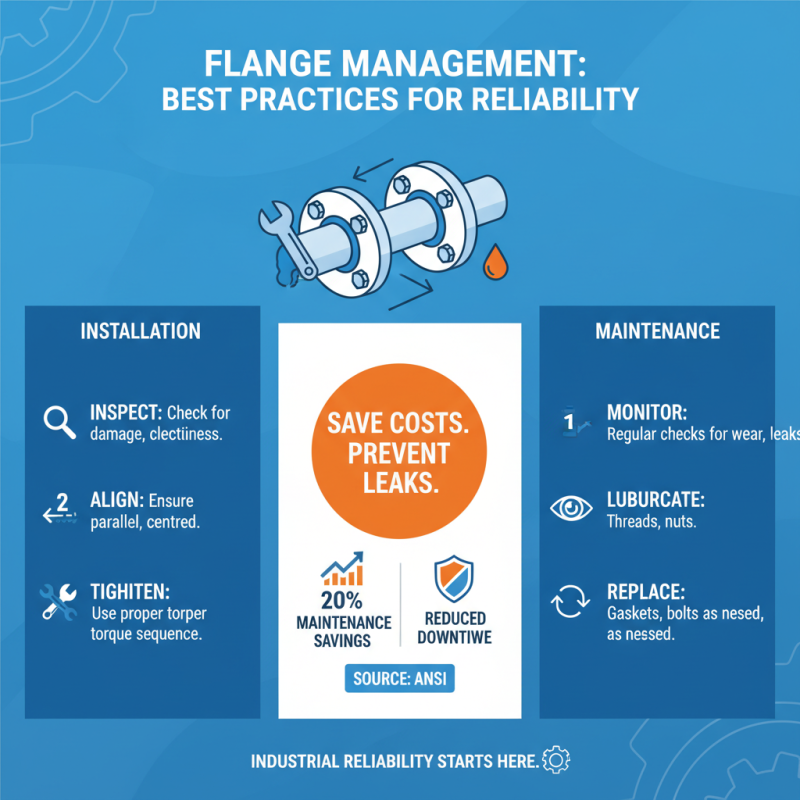

Effective installation and maintenance of pipe flanges are crucial for industrial operations. Research indicates that improper flange assembly can lead to leaks and costly downtime. According to the American National Standards Institute, nearly 20% of maintenance costs stem from inappropriate flange management. This makes it vital to follow best practices.

Tips: Always inspect flange surfaces before installation. Damaged or dirty surfaces can compromise the seal. A clean surface ensures a proper fit, reducing the risk of leakage.

When tightening flanges, use a reliable torque wrench. Over-tightening can cause flange warping or breakage. Industry studies recommend a tightening sequence to evenly distribute pressure. This method reduces stress points and increases durability.

Regular maintenance checks are essential. Inspect bolts for corrosion and functionality. It’s advisable to replace worn-out bolts instead of reusing them. Furthermore, documentation of maintenance activities can help track potential failures. Always prioritize safety protocols during inspections.

The Role of Pipe Flanges in Ensuring System Integrity and Safety

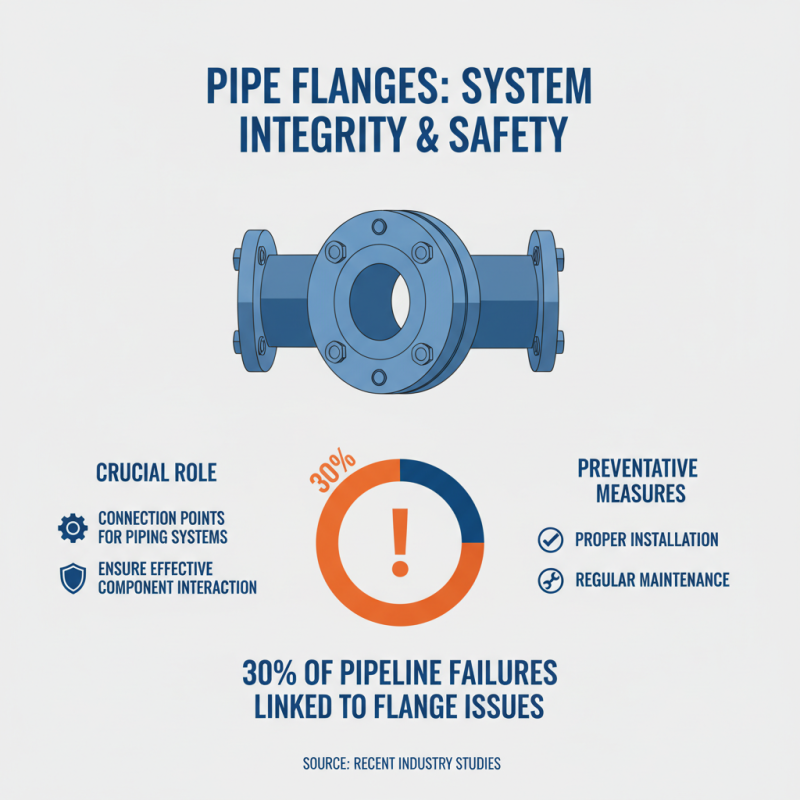

Pipe flanges play a crucial role in maintaining system integrity and safety in industrial applications. They provide connection points for piping systems, ensuring that the components work together effectively. According to recent studies, about 30% of pipeline failures are linked to flange issues. This highlights the necessity for proper installation and maintenance practices.

In high-pressure environments, flanges must withstand significant stress. A malfunction can lead to leaks or ruptures, posing safety hazards. Reports indicate that safety incidents related to flanges cost the industry over $1 billion annually. These figures emphasize the importance of using quality materials and adhering to installation guidelines.

While many industries rely on flanges, improper sealing and alignment can occur. Inadequate quality control measures or subpar materials increase risks. Regular inspections are essential to identify potential failures. In some cases, operators overlook this aspect, leading to costly repairs. Addressing these vulnerabilities can significantly enhance system reliability.

Related Posts

-

Why Hot Rolled Coil is Essential for Construction and Manufacturing Industries

-

How to Choose the Right Inconel Pipe for Your Project Needs

-

Top 10 Benefits of Using 304 Stainless Steel Pipe in Modern Construction

-

2025 Top 10 Advantages of Using Mild Steel Pipes for Construction

-

Top 10 Tips for Working with 2205 Duplex Stainless Steel Applications

-

How to Choose the Right Seamless Steel Pipe for Your Project Needs

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil