How to Choose the Right Stainless Steel Tube for Your Project Needs

When it comes to selecting the right stainless steel tube for your project needs, understanding the various factors that influence this choice is crucial. According to a recent report by the Global Market Insights, the stainless steel tube market was valued at over $40 billion in 2022 and is projected to grow at a CAGR of approximately 5% from 2023 to 2030. This growth is propelled by the increasing demand across industries such as construction, automotive, and aerospace, where the unique properties of stainless steel, including its corrosion resistance and strength, are highly valued.

In the context of specific applications, the right selection of a stainless steel tube can significantly impact both performance and cost-effectiveness. The selection process involves considering various parameters such as the grade of stainless steel, wall thickness, and tube dimensions. These parameters are essential as they dictate the tube’s ability to withstand pressure, temperature variations, and potential corrosive environments. As outlined in industry guidelines, adhering to these technical specifications can enhance product longevity and functionality, ultimately leading to successful project outcomes.

Understanding the Types of Stainless Steel Tubes Available

When selecting the right stainless steel tube for your project, it's essential to understand the various types available and their specific applications. Stainless steel tubes are primarily categorized into two main types: seamless and welded. Seamless tubes are manufactured through a piercing process and are known for their strength and durability, making them ideal for high-pressure applications, such as in the oil and gas industry. According to a report by the Global Stainless Steel Tubes Market, seamless tubes account for approximately 60% of the total market share, largely due to their superior mechanical properties.

Welded tubes, on the other hand, are produced by forming a strip of stainless steel into a tube and welding the edges together. These tubes are generally more cost-effective and suitable for low-pressure applications, including plumbing and structural components. Industry reports indicate that the demand for welded stainless steel tubes has been growing steadily, with projections estimating a CAGR of 4.2% over the next five years, driven by increased infrastructure development across various sectors. Understanding these distinctions and the applications of different types of stainless steel tubes is crucial for making an informed decision tailored to the specific needs of any project.

Evaluating the Mechanical Properties of Stainless Steel Tubes

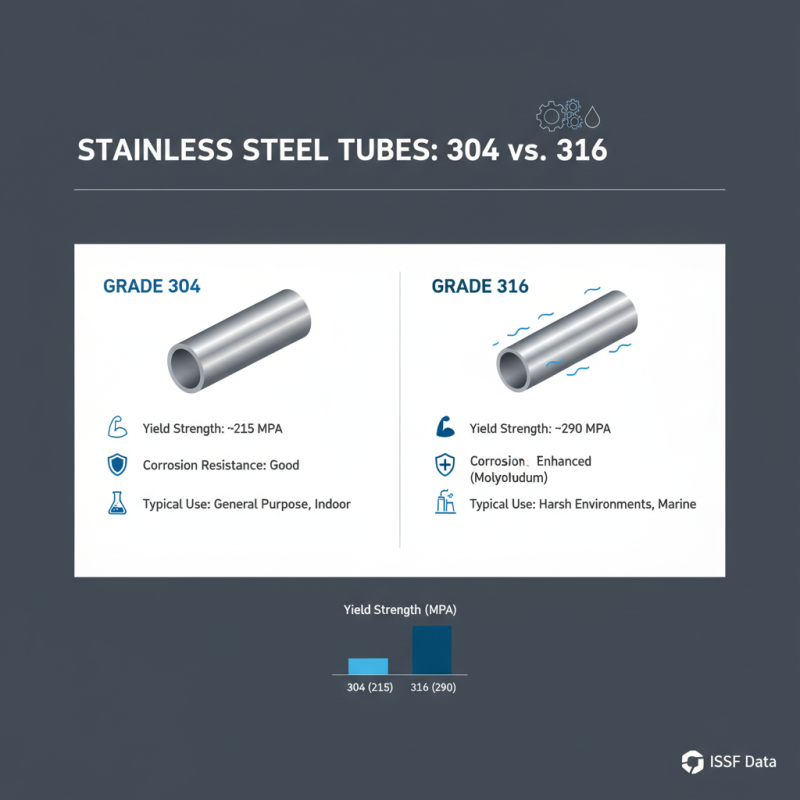

When selecting the appropriate stainless steel tube for your project, understanding the mechanical properties of the material is crucial. Stainless steel tubes are typically characterized by their strength, corrosion resistance, and ductility, which are largely influenced by their composition and manufacturing processes. According to the International Stainless Steel Forum (ISSF), common grades like 304 and 316 exhibit different mechanical properties, with 316 offering enhanced corrosion resistance due to the presence of molybdenum. The yield strength of 304 stainless steel is approximately 215 MPa, whereas 316 typically has a yield strength around 290 MPa, making it a preferred choice for applications subject to harsher environments.

In addition to strength, tensile strength is another vital mechanical property to consider. The tensile strength of the 304 grade can reach about 505 MPa, while 316 can achieve 580 MPa. This distinction can significantly impact the performance of stainless steel tubes in structural applications. Furthermore, elongation percentage indicates the material's ductility; for instance, 304 stainless steel generally possesses an elongation of 40%, indicating it can deform significantly before failure. Understanding these properties allows engineers and designers to select tubes that not only meet the performance requirements of their projects but also ensure longevity and reliability in their applications.

Identifying the Correct Size and Dimensions for Your Project

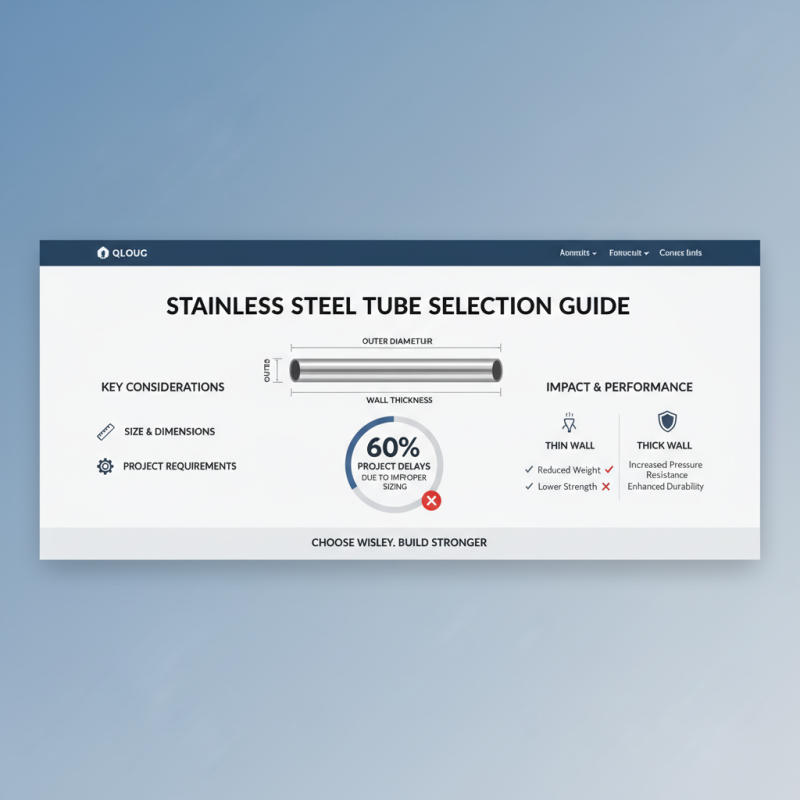

When selecting the right stainless steel tube for your project, it’s crucial to carefully consider the size and dimensions that best fit your requirements. According to recent industry reports, approximately 60% of projects are delayed due to improper sizing of components, often leading to inefficiencies and increased costs. Understanding the specifications needed for your application, such as the outer diameter and wall thickness, can significantly impact the performance and durability of your structure. For instance, a thinner wall may reduce weight but could compromise strength, while a thicker wall will offer greater resistance to pressure and external forces.

Tips: Always refer to the American Society for Testing and Materials (ASTM) standards, which provide essential guidelines on the dimensions and qualities of stainless steel products. Additionally, consulting with a structural engineer can help ensure that you select the most suitable dimensions for your project needs, especially in applications involving high-stress environments.

Furthermore, consider the environment in which the stainless steel tube will be used. Different applications require different tolerances. For example, is the tube for a high-temperature application or exposure to corrosive substances? Industry research indicates that the right selection can improve lifespan by up to 40%. Thus, investing time in defining the precise dimensions will lead to enhanced functionality and a long-lasting project outcome.

Considering Corrosion Resistance and Environmental Factors

When selecting the right stainless steel tube for your project, considering corrosion resistance is paramount. Stainless steel is renowned for its durability and resistance to oxidation, but different grades of stainless steel offer various levels of protection against specific corrosive environments. For instance, certain projects may encounter high humidity, exposure to chemicals, or saline conditions, which can accelerate corrosion. In such cases, opting for higher alloy content, such as 316 stainless steel, can greatly enhance performance and longevity, ensuring that the material withstands environmental stressors over time.

Environmental factors also play a crucial role in the selection process. The geographic location, climate, and potential exposure to various corrosive agents, such as saltwater or industrial chemicals, must be thoroughly evaluated. Additionally, the intended application—whether for outdoor structures, marine environments, or industrial settings—can influence the choice of stainless steel type. Understanding these environmental conditions allows for informed decisions that align with both the durability requirements and cost-effectiveness of the project, ultimately leading to a successful and sustainable outcome in any engineering endeavor.

How to Choose the Right Stainless Steel Tube for Your Project Needs

| Tube Type | Corrosion Resistance Rating | Environmental Considerations | Common Applications |

|---|---|---|---|

| 304 Stainless Steel | Moderate | Mild environments; not suitable for chloride exposure | Food processing, kitchen equipment |

| 316 Stainless Steel | High | Coastal or marine environments | Chemical processing, marine applications |

| 430 Stainless Steel | Low to moderate | Dry environments; avoids high humidity | Automotive trim, appliances |

| Duplex Stainless Steel | Very high | Challenging environments with high stress | Oil and gas, chemical industries |

Assessing Cost and Availability for Your Stainless Steel Tube Needs

When selecting the right stainless steel tube for your project, assessing cost and availability is crucial. According to a recent industry report, the stainless steel market is projected to grow at a CAGR of 5.1% through 2027, indicating a steady demand that can impact supply chains. It's vital to evaluate not just the upfront costs of the materials but also the long-term implications of availability, especially during periods of heightened demand or supply chain disruptions that can influence pricing and access to specific grades of stainless steel.

Tips to consider include researching local suppliers to determine real-time availability and cost competitiveness. Additionally, consider the potential for bulk purchasing discounts or negotiations for better pricing based on project volume. Awareness of global market trends, such as fluctuations in nickel prices—which constitute around 8-12% of stainless steel—can also provide insights into potential cost increases that may affect your project budget.

Furthermore, understanding the various grades and specifications of stainless steel tubes can help in making an informed choice based on not just cost but also longevity and maintenance. According to a study by the International Stainless Steel Forum, higher-grade stainless steel often leads to lower lifecycle costs despite their initial price, due to better corrosion resistance and durability, making them a wise investment in the long run. Consider these factors carefully to find a suitable balance between cost efficiency and material quality for your project's unique needs.

Stainless Steel Tube Cost and Availability Analysis

Related Posts

-

How to Choose the Best 2 Inch Stainless Steel Pipe for Your Project

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

Top 10 Benefits of Using 304 Stainless Steel Pipe in Modern Construction

-

2025 Top 10 Advantages of Using Mild Steel Pipes for Construction

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

How to Choose the Right Steel Pipes and Fittings for Your Projects

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil