How to Choose the Right Pipe Flange for Your Project?

Choosing the right pipe flange for your project can be challenging. John Smith, a renowned expert in the piping industry, once stated, "The correct flange can make or break your installation." This insight underscores the importance of careful consideration when selecting a pipe flange.

A pipe flange connects pipes, fittings, and valves. It is essential to ensure that the selected flange matches your project's requirements. Different materials, pressure ratings, and sizes must all be evaluated. The consequences of a poor choice can lead to leaks or failures, causing safety and operational issues.

When navigating these options, visualize the specific application. Consider the environment, the type of fluids involved, and the pressure levels. Each detail matters. Reflecting on past experiences can also inform decisions. What worked well before? What didn't? It's crucial to embrace these reflections to avoid past mistakes and improve future outcomes.

Factors to Consider When Selecting Pipe Flanges for Industrial Applications

When selecting pipe flanges for industrial applications, several factors come into play.

Material compatibility is crucial.

Flanges can be made from various materials like carbon steel, stainless steel, and plastic.

Evaluate the fluid or gas being transported. Corrosive substances may require more resistant materials.

Pressure ratings

must match the system's requirements. Make sure to consider the operational conditions.

High-pressure environments need flanges that can handle the stress.

Many flanges are rated by standard specifications. Understanding these ratings can prevent failures.

Tip: Always check the flange dimensions.

Standard sizes may not fit specific systems.

It’s wise to measure before purchasing.

Another consideration is the environment where the flanges will be used.

For example, outdoor settings may lead to corrosion.

Choosing flanges with protective coatings can be beneficial.

Evaluate if your project requires additional features, like gaskets.

These can enhance sealing and improve performance.

Remember, a wrong choice can result in leaks or

system failures. Take time to research.

Consult with experts if needed.

Understanding Different Pipe Flange Types: A Comprehensive Overview

Choosing the right pipe flange is crucial for any piping project. Different types of flanges serve specific purposes. Understanding these can save you time and resources.

Weld neck flanges are often used for high-pressure applications. Their design allows for strong, long-lasting connections. Slip-on flanges are easier to install but may not hold up as well under high stress. Each type has its pros and cons, so think carefully about your needs.

**Tips:** Always consider the working pressure. Match the flange type to prevent future issues. Inspect materials as well. Not all flanges are created equal.

Blind flanges serve as a seal for an end of a pipe system. They're useful for maintenance and testing. However, ensure they fit your piping specifications. Using the wrong size can lead to leaks.

**Tips:** Check compatibility with your system. Always measure accurately before purchasing. It can save headaches later.

Material Selection for Pipe Flanges: Balancing Strength and Corrosion Resistance

When selecting pipe flanges, choosing the right material is crucial. The balance between strength and corrosion resistance directly impacts the longevity of your project. Steel flanges are strong but may corrode if not properly treated. Stainless steel offers better corrosion resistance but can be more expensive.

Consider the environment where the flange will be used. For instance, underwater operations require materials that can withstand high pressure and corrosion. In contrast, indoor applications might need less robust solutions. Being aware of your project’s specific conditions is important.

Tips:

- Always consult material data sheets.

- Consider the temperature and pressure ratings.

- Evaluate your budget in relation to material durability.

Choosing the right material often involves trade-offs. Some projects may prioritize cost over durability, leading to future repairs. It's vital to reflect on these aspects to avoid potential issues down the line.

Material Selection for Pipe Flanges: Strength vs. Corrosion Resistance

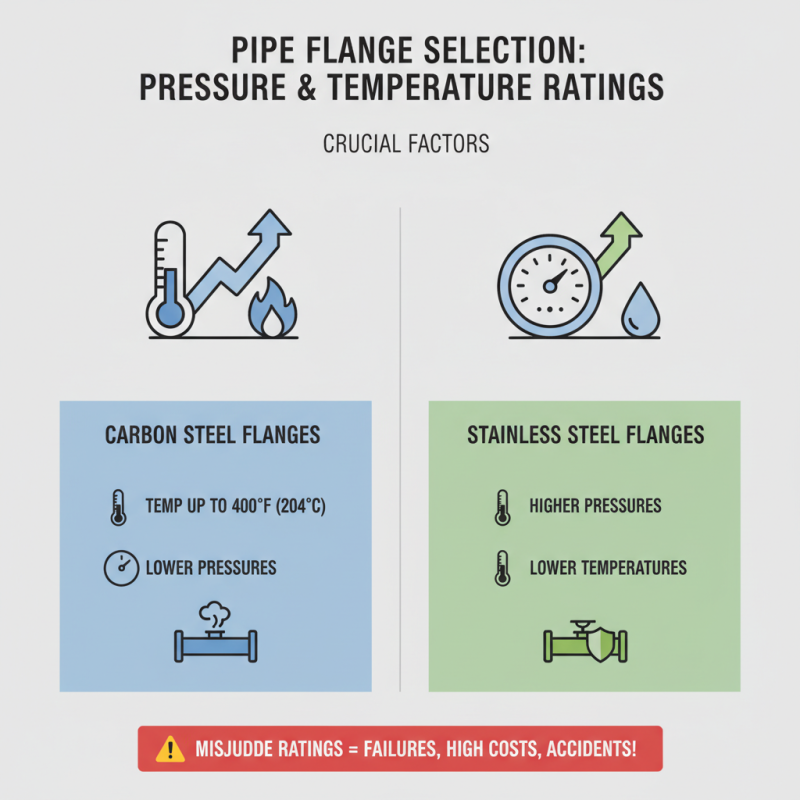

Assessing Pressure and Temperature Ratings for Flange Longevity

When selecting pipe flanges, understanding pressure and temperature ratings is crucial. Different materials handle different conditions. For example, carbon steel flanges can withstand temperatures up to 400°F(204°C) at lower pressures, while stainless steel options typically manage higher pressures but lower temperatures. Misjudging these ratings can lead to failures, increased maintenance costs, or even severe accidents.

Reports show that 70% of flange failures occur due to pressure miscalculations. This highlights the necessity for thorough assessment. Consider the working environment: will the flange face corrosion? Is there a risk of thermal expansion? These factors alter performance expectations. Furthermore, every project has unique demands. A single misstep in pressure or temperature evaluation can result in a weak link within the system.

It's a challenging balance. Flanges must also match the specific pipeline requirements. Oversizing or undersizing can create unexpected vulnerabilities. For instance, a flange rated for high pressure but used in a low-pressure system may exhibit unnecessary wear. The industry must remain vigilant. Regular reassessment of material capabilities against operating conditions is essential for durability and functionality.

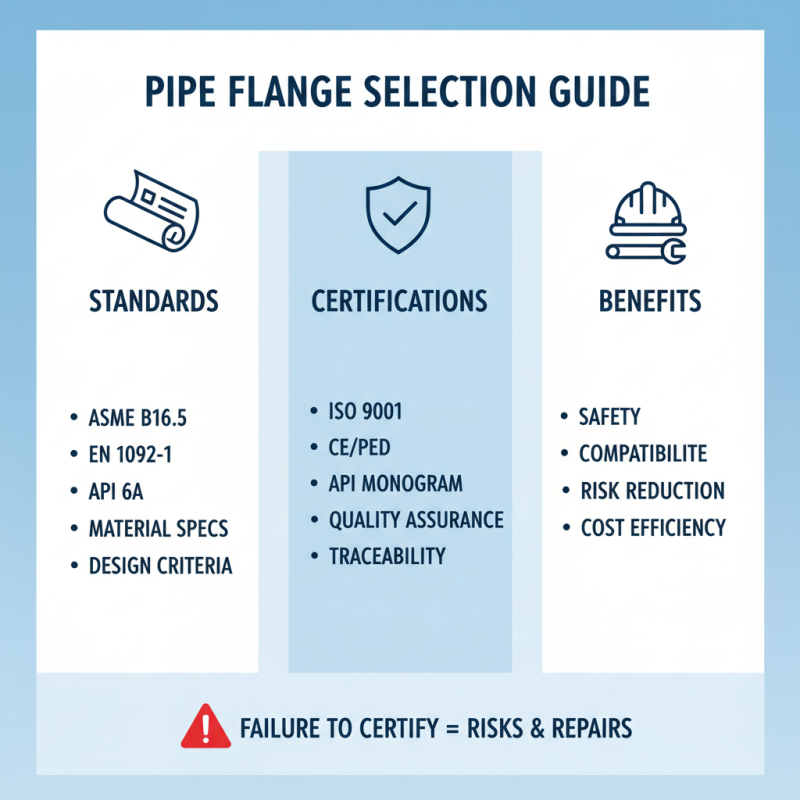

The Importance of Standards and Certifications in Flange Selection Process

Choosing the right pipe flange requires attention to standards and certifications. These guidelines ensure safety and compatibility. Using certified flanges minimizes risks in your project. Standards provide essential information on material properties and design criteria. They help maintain industry integrity. Without proper certification, you could face failures or costly repairs.

Some tips to consider: Verify the flange specifications match your project needs. Assess the pressure and temperature ratings. Review the material since it impacts durability. Trust those with relevant certifications. A lack of proper certification may lead to subpar performance.

When in doubt, consult experts in the field. They can guide you to suitable options. Remember, skipping this step can result in future complications. Address the possibility of human error too. Even the most qualified professionals make mistakes. Engaging with certified professionals can help mitigate such risks. Taking these steps ensures a more successful outcome.

Related Posts

-

Top SS Pipe Fittings Guide for Ultimate Performance and Durability

-

Why Pipe Flanges Are Essential for Industrial Applications?

-

Why Hot Rolled Coil is Essential for Construction and Manufacturing Industries

-

Top 10 Stainless Steel Pipe Sizes You Need to Know in 2026

-

Top Benefits of Using Carbon Steel Pipe in Construction and Industry

-

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil