How to Choose the Right Inconel Pipe for Your Project Needs

When embarking on a project that requires the use of specialized materials, selecting the right Inconel pipe is critical to ensuring optimal performance and longevity. Inconel pipes, known for their exceptional resistance to heat and corrosion, are commonly employed in industries ranging from aerospace to chemical processing. As industry expert Dr. Sarah Thompson states, "Choosing the right Inconel pipe can make the difference between a successful project and costly downtimes." This statement underscores the importance of understanding the specific needs and constraints of your application before making a decision.

In the realm of Inconel pipes, various grades and specifications exist, each tailored for different environments and uses. Factors such as temperature, pressure, and the corrosive nature of the substances handled all play a pivotal role in determining the ideal type of Inconel pipe for your project. Therefore, it is essential for engineers and project managers to consider these criteria carefully. Armed with the right information and guidance, stakeholders can optimize their material choices, ensuring their projects achieve desired outcomes while minimizing risks.

Understanding Inconel and Its Applications in Various Industries

Inconel, a family of austenitic nickel-chromium-based superalloys, is renowned for its remarkable resistance to oxidation and corrosion, making it a preferred choice in various industrial applications. The properties of Inconel allow it to withstand extreme temperatures and aggressive environments, characteristics that are critical in industries such as aerospace, chemical processing, and oil and gas. According to a report by Markets and Markets, the global market for superalloys, including Inconel, is projected to reach USD 10.8 billion by 2025, driven by rising demand in critical sectors.

In the aerospace industry, Inconel pipes are crucial for jet engines and gas turbines due to their ability to maintain mechanical strength at elevated temperatures. Data from a recent report by Mordor Intelligence highlights that the aerospace sector holds a significant share of the global Inconel market, primarily because of its stringent requirements for high-performance materials. Furthermore, in the chemical processing industry, Inconel’s resistance to corrosive environments allows for safe handling of aggressive chemicals, reducing the risk of leaks and failures. Additionally, applications in the oil and gas sector benefit from Inconel’s ability to withstand high pressures and temperatures, ensuring operational reliability in challenging conditions. These applications demonstrate the versatility of Inconel and its integral role in advancing engineering solutions across many industries.

Inconel Pipe Usage in Various Industries

Key Factors to Consider When Selecting Inconel Pipe Specifications

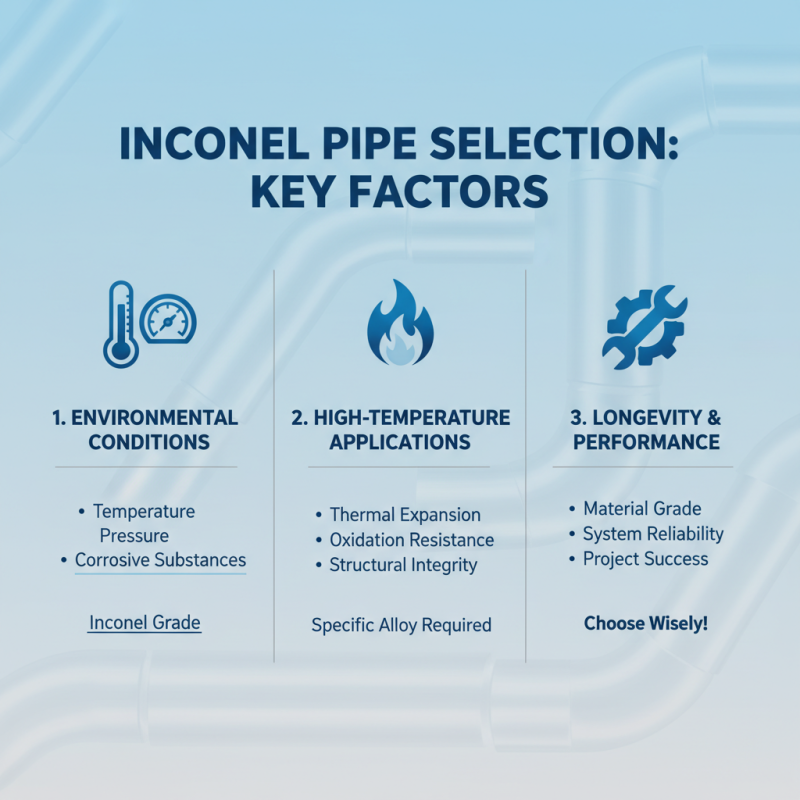

When selecting Inconel pipes for your project, there are several key factors to consider that can greatly affect the performance and longevity of your piping system. First and foremost, you need to evaluate the specific environmental conditions the pipes will be subjected to. Factors such as temperature, pressure, and exposure to corrosive substances can significantly influence the appropriate grade of Inconel. For instance, high-temperature applications may require a specific alloy formulation that can withstand thermal expansion and oxidation while maintaining structural integrity.

Another crucial factor is the intended application of the Inconel pipe. Different industries may have unique requirements regarding mechanical properties such as tensile strength, weldability, and fatigue resistance. It is essential to match the pipe specifications with the operational demands of your project, ensuring compatibility with other materials and components within the system. Additionally, understanding standards and certifications relevant to your industry can help ensure compliance and enhance safety, reliability, and efficiency in your project outcomes. By carefully assessing these factors, you can make informed decisions in selecting the right Inconel pipe to meet your specific project needs.

Comparing Different Grades of Inconel for Project Requirements

When selecting the right Inconel pipe for your project, understanding the different grades available is crucial. Inconel, a family of austenitic nickel-chromium-based alloys, is known for its excellent high-temperature strength, oxidation resistance, and corrosion resistance. The most commonly used grades include Inconel 600, 625, and 718. Each grade has distinct properties that make it suitable for specific applications, and comparing these can help you make an informed decision.

Inconel 600 is often chosen for its resistance to oxidation and carburization, making it ideal for high-temperature applications. This grade performs well in environments that may involve sulfur compounds and is commonly used in chemical processing and furnace components. On the other hand, Inconel 625 offers enhanced strength and fatigue resistance, particularly in marine and chemical processing environments. Its versatility makes it a preferred choice for applications subjected to extreme conditions, including subsea components. Finally, Inconel 718, known for its impressive mechanical properties and high yield strength, is frequently utilized in aerospace and oil field applications due to its weldability and resistance to various corrosive media.

Understanding the specific requirements of your project is essential while choosing amongst these grades. Factors such as temperature range, exposure to corrosive substances, and required mechanical strength should heavily influence your selection. By carefully weighing the characteristics of each Inconel grade, you can ensure that your project will benefit from optimal performance and durability.

Assessing the Role of Pipe Size and Thickness in Performance

When selecting the right Inconel pipe for your project, it's crucial to assess both the size and thickness, as these factors significantly impact performance. The diameter of the pipe determines the flow capacity and can affect pressure drop, which is particularly important in systems where fluid transportation is key. A larger diameter can facilitate a higher flow rate but may also necessitate more robust supports and fittings due to the increased weight. Conversely, smaller pipes can be advantageous in terms of reduced material costs and ease of installation, but they may result in higher friction losses, diminishing efficiency.

Thickness is another critical aspect when choosing Inconel pipes. The wall thickness not only influences the pipe’s pressure rating but also its resistance to external forces and corrosion. Thicker pipes can withstand higher pressures and harsh environments, making them ideal for applications in industries such as aerospace and petrochemicals. However, the cost implications of thicker materials need to be considered, especially in larger projects where budget constraints may be at play. Ultimately, the right balance between size and thickness will depend on the specific requirements of your application, dictating the longevity and reliability of the system in which the pipes will be utilized.

Evaluating Cost-Effectiveness and Availability of Inconel Pipes

When selecting Inconel pipes for your project, a key consideration is the cost-effectiveness of the material. Inconel, renowned for its high strength and corrosion resistance, often comes with a higher price tag compared to standard pipe materials. It is essential to evaluate not just the upfront costs but also the long-term benefits, such as reduced maintenance needs and greater durability in extreme environments.

Analyzing the total lifecycle costs can help determine whether investing in Inconel pipes will yield savings in the future.

Availability is another crucial factor when assessing your options. The market for Inconel pipes can fluctuate based on demand and supply chain factors. It's important to ensure that the pipes you require are readily available for immediate purchase or can be procured within a reasonable timeframe.

Engaging with multiple suppliers and understanding the lead times and inventory levels can help mitigate potential delays in your project timeline. By weighing both cost and availability, you can make an informed decision that aligns with your project's specific needs and objectives.

Related Posts

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

Top Benefits of Using Carbon Steel Pipe in Construction and Industry

-

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

-

2025 Top 10 Advantages of Using Mild Steel Pipes for Construction

-

How to Choose the Right Seamless Steel Pipe for Your Project Needs

-

Top 10 Benefits of Using Stainless Steel 316L in Your Projects

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil