How to Choose the Best Stainless Steel Material for Your Project?

Choosing the right stainless steel material for your project can be challenging. Different grades and finishes exist, each serving specific needs. You may feel overwhelmed by the options available.

Stainless steel material is renowned for its strength and resistance to rust. However, selecting the wrong type can lead to future complications. For instance, certain grades can be more prone to scratches. Learning about these differences is crucial to making an informed decision.

Consider your project's environment. Will it face extreme temperatures or corrosive elements? Answering this helps narrow down your choices. It’s essential to reflect on the long-term implications of your selection, as choosing the right material today safeguards your project for years to come.

Understanding the Basics of Stainless Steel Materials

When diving into stainless steel materials, it’s vital to grasp the different types and their properties. Various grades exist, like 304 and 316, each offering distinct benefits. Data indicates that around 70% of stainless steel produced globally is grade 304. It's favored for its versatility and excellent corrosion resistance, making it ideal for many applications.

In contrast, grade 316, which contains molybdenum, excels in harsher environments. Reports show it resists pitting in chloride environments, crucial for marine applications. Interestingly, while 316 often holds the edge for durability, it is also more costly. Budget constraints might lead you to reconsider if the additional expense justifies the benefits for your project.

Choosing the right stainless steel isn’t always straightforward. Many assume that a higher grade guarantees better performance. However, that's not a given. A clearer focus on the specific needs of your project, such as exposure to chemicals or temperature variations, can lead to a more suitable choice. Neglecting these details may result in unexpected issues down the line. Balancing cost and performance requires critical thinking and sometimes, reassessment of project specifications.

Stainless Steel Material Comparison for Projects

This chart compares different types of stainless steel materials based on key properties such as corrosion resistance, tensile strength, and cost. Each type serves its purpose in various applications, and understanding these properties helps in choosing the right material for your project.

Types of Stainless Steel and Their Properties

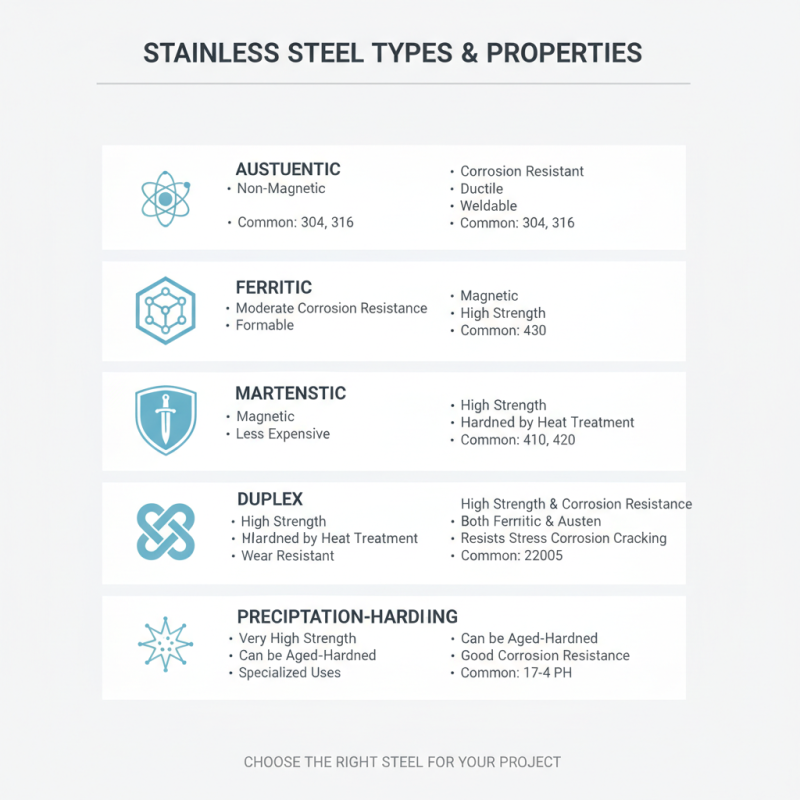

When selecting stainless steel for your project, understanding the types and their properties is essential. There are primarily five categories of stainless steel: austenitic, ferritic, martensitic, duplex, and precipitation-hardening. Each type possesses distinct characteristics that cater to various applications.

Austenitic stainless steels, like 304 and 316, are known for their excellent corrosion resistance and ductility. They account for over 70% of stainless steel production. Ferritic grades, including 430, are magnetic and more affordable but less resistant to pitting corrosion. The selection might seem straightforward, but it's crucial to evaluate specific environmental conditions, as corrosion resistance varies significantly.

Martensitic stainless steels, like 410 and 420, provide good hardness and strength but can be less resistant to corrosion. Duplex stainless steels combine austenitic and ferritic properties, offering a balance of strength and corrosion resistance. However, these can also be more costly. Precipitation-hardening steels encompass a wide range of properties but usually require careful heat treatment processes, which might complicate manufacturing.

Understanding these properties can help ensure your project’s durability. Analyzing factors such as stress, temperature, and exposure to chemicals can affect your choice. Reflecting on the implications of these materials on your project's longevity is critical as not all options may be feasible or optimal in practice.

Key Factors to Consider When Choosing Stainless Steel

When choosing stainless steel for your project, several key factors come into play. The grade of stainless steel is crucial. Different grades have varying properties. For instance, some excel in corrosion resistance, while others are strong and durable. Pay attention to the specific environment where the steel will be used. This includes exposure to moisture, chemicals, or extreme temperatures. Sometimes people overlook these details, leading to poor choices.

Another important factor is the finish of the stainless steel. A polished surface may look more appealing, but it can be less resistant to scratches. On the other hand, a matte finish might hide blemishes and wear better over time. Think about the aesthetics versus the functionality of the finish. You may need to experiment to find what suits your needs best.

Lastly, consider your budget. While it’s tempting to go for the cheapest option, this can lead to higher costs later if you need replacements or repairs. It’s a delicate balance between quality and cost. Reflect on what matters most for your project—longevity or initial investment. Each choice has its trade-offs, and understanding these can guide you in making a wiser decision.

How to Choose the Best Stainless Steel Material for Your Project? - Key Factors to Consider When Choosing Stainless Steel

| Stainless Steel Grade | Corrosion Resistance | Strength | Weldability | Common Applications |

|---|---|---|---|---|

| 304 | Good | Medium | Good | Kitchen Equipment, Food Processing |

| 316 | Excellent | Medium | Good | Marine Applications, Chemical Processing |

| 430 | Fair | High | Fair | Automotive Trim, Decorative Items |

| 2205 | Excellent | Very High | Good | Oil & Gas, Structural Applications |

| 309 | Good | High | Excellent | High-Temperature Applications |

Applications and Industries for Different Stainless Steel Grades

When selecting stainless steel for a project, understanding its applications is key. Different grades of stainless steel serve various industries. For example, 304 stainless steel is popular in food processing. It resists corrosion and is easy to clean, making it ideal for kitchen equipment. Its versatility allows it to be used in everything from sinks to countertops.

In contrast, 316 stainless steel is preferred in marine environments. It has added molybdenum, which enhances resistance to saltwater. This makes it suitable for boat fittings and coastal structures. However, it's heavier and more expensive, which might not always suit every budget. In chemical processing, 321 stainless steel is favored for its stability and resistance to high temperatures.

Remember, the selection process may have flaws. A common mistake is choosing based solely on appearance. Performance and functionality should take precedence. Different projects require different properties, so always reflect on your specific needs. Choosing the right grade is crucial for long-lasting results.

Maintenance and Longevity of Stainless Steel in Projects

When it comes to the maintenance and longevity of stainless steel in projects, understanding its characteristics is crucial. Stainless steel is known for its resistance to corrosion and staining, making it ideal for various applications. However, it is not entirely maintenance-free. Regular cleaning is necessary to preserve its appearance and functionality. Studies indicate that 80% of stainless steel issues arise from improper maintenance.

Tips: Use a mild detergent and warm water for cleaning. Avoid harsh chemicals that can damage the surface.

Stainless steel can last for decades if cared for properly. The alloy composition plays a significant role in its durability. For example, 316 stainless steel is often recommended for marine environments due to its enhanced corrosion resistance. However, even high-grade stainless steel can show signs of wear over time, especially in harsh conditions.

Tips: Inspect your stainless steel regularly. Look for signs of pitting or discoloration to catch issues early.

Ultimately, while stainless steel provides incredible benefits, it requires attention and care. Neglecting maintenance can lead to costly repairs or replacements. Understanding the specific needs of your stainless steel project can greatly enhance its life and performance.

Related Posts

-

How to Choose the Right Steel Pipes and Fittings for Your Projects

-

How to Choose the Best 2 Inch Stainless Steel Pipe for Your Project

-

Top 10 Stainless Steel Pipe Sizes You Need to Know in 2026

-

How to Choose Stainless Steel 316L for Your Projects?

-

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

-

Top Stainless Fittings Types for Your Next Project?

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil