How to Choose the Right Steel Pipes and Fittings for Your Projects

Choosing the right steel pipes and fittings is crucial for ensuring the integrity and efficiency of any construction or industrial project. According to a report by the Global Steel Pipes and Fittings Market Analysis, the market is projected to reach USD 70 billion by 2026, driven by increasing demand across various sectors including construction, oil and gas, and manufacturing. This statistic underscores the importance of making informed decisions in selecting high-quality piping products that meet specific project requirements.

Industry expert Dr. John Stevens, a leading figure in materials engineering, emphasizes the significance of this choice, stating, "The selection of appropriate steel pipes and fittings can significantly impact both the performance and longevity of the infrastructure." His insights highlight that not only the specifications, such as size and material grade, but also the intended application, are vital factors in the decision-making process.

As projects become increasingly complex and regulatory standards tighten, understanding the diverse range of steel pipes and fittings available is more important than ever. By leveraging expert knowledge and industry data, project managers and engineers can ensure they select the right materials that not only comply with safety standards but also contribute to cost-effective and sustainable project outcomes.

Factors to Consider When Selecting Steel Pipes for Construction Projects

When selecting steel pipes for construction projects, several critical factors must be taken into account to ensure optimal performance and longevity. First, consider the purpose of the pipes. Different applications may require varying grades of steel or pipe sizes based on the expected load and environmental conditions. For instance, pipes used in high-pressure systems need to be made from high-strength steel to withstand intense pressure, while those in drainage systems may prioritize corrosion resistance.

Another essential factor is the pipe's diameter and wall thickness, which directly impacts flow rates and structural integrity. The correct sizing is vital to meet project specifications and ensure the efficient passage of materials like water or gas. Improper sizing can lead to increased wear and potential failure of the system.

Tips: Always examine the compatibility of the pipe materials with the substances they will transport. Incompatible materials can lead to corrosion or degradation, shortening the lifespan of the installation. Additionally, consulting with industry professionals or using available calculators can aid in determining the right specifications for your project's needs, resulting in a more effective and cost-efficient solution.

Types of Steel Pipes and Their Applications in Various Industries

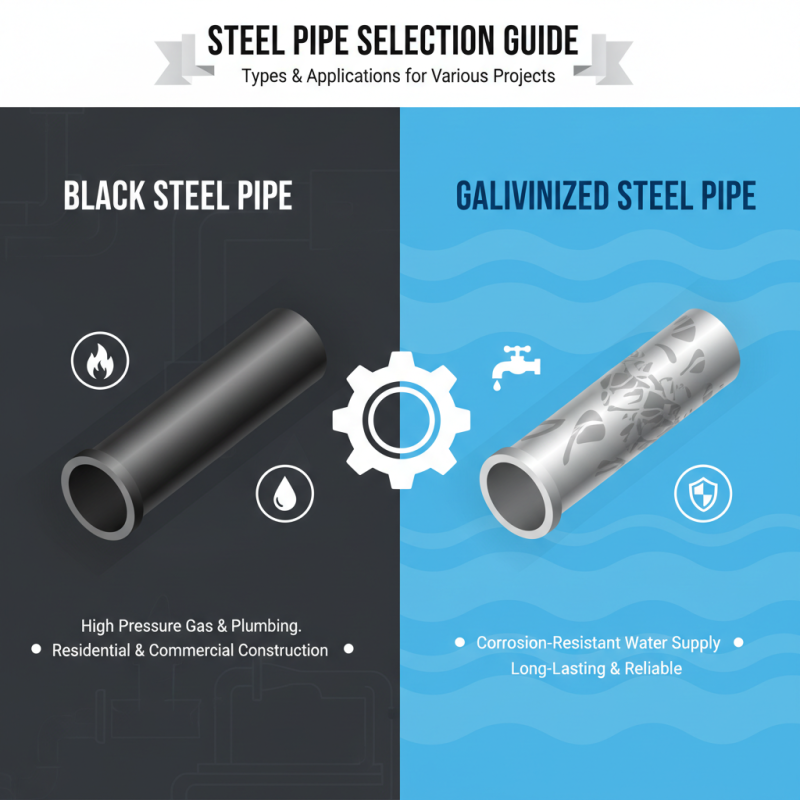

When selecting steel pipes for various projects, it is crucial to understand the types available and their specific applications across different industries. One common type is the black steel pipe, which is widely used in gas distribution and plumbing systems due to its ability to handle high pressures. Its durability and strength make it suitable for residential and commercial construction. Similarly, galvanized steel pipes, coated with zinc to resist corrosion, are often utilized in water supply systems, ensuring longevity and reliability in various environmental conditions.

Another important category is stainless steel pipes, known for their resistance to rust and corrosion. They are extensively used in food processing, medical applications, and chemical industries where hygiene and contamination prevention are critical. Additionally, carbon steel pipes, praised for their strength and versatility, are ideal for construction, oil, and gas applications, making them a go-to choice for infrastructure projects. Understanding the distinct properties and applications of these steel pipe types can greatly enhance the efficiency and safety of your projects.

Understanding Pipe Sizes and Schedules for Your Specific Needs

When selecting steel pipes and fittings for your projects, understanding pipe sizes and schedules is crucial to ensuring that your installation meets both operational demands and regulatory standards. Pipe size typically refers to its diameter, which can significantly impact the flow rate and pressure capacity of a piping system. It's essential to choose a size that accommodates the expected volume of fluid or gas while factoring in space constraints and connection points.

In addition to diameter, the schedule of a pipe provides insight into its wall thickness, which directly relates to its strength and pressure rating. Common schedules, such as Schedule 40 or Schedule 80, define the maximum operating pressures and dictate how the pipes will function under various conditions. For projects that require high-pressure applications, opting for a higher schedule will ensure the structural integrity of the piping system and help avoid potential failures. Therefore, carefully assessing your project's specific needs in terms of pipe size and schedule will lead to more effective and safe installations.

Choosing the Right Fittings to Complement Your Steel Pipes

When selecting fittings to complement your steel pipes, it’s essential to understand the various types available and their specific applications. Steel pipe fittings come in a range of configurations such as elbows, tees, reducers, and couplings, each designed to connect, join, or alter the direction of pipelines. Understanding the purpose of each fitting type is crucial for ensuring the integrity and efficiency of your piping system. For example, using a 90-degree elbow is ideal for changing the direction of flow, while a tee fitting is necessary for branching off a line.

Compatibility is another critical factor when choosing fittings. Not all fittings are suitable for every type of steel pipe, so it’s important to ensure that the fittings made from similar materials and designed to handle the same pressure ratings as your pipes. Additionally, consider the connection types—threaded, welded, or flanged fittings each have their advantages depending on the application. Properly selecting fittings not only enhances the performance of the piping system but also conforms to safety standards and supports longevity, reducing the need for costly repairs or replacements in the future.

Steel Pipes and Fittings Selection - Quality vs. Cost

Common Mistakes to Avoid When Sourcing Steel Pipes and Fittings

When sourcing steel pipes and fittings for your projects, one of the most common mistakes is not thoroughly assessing your project requirements. Before making a purchase, it is crucial to understand the specific specifications such as diameter, wall thickness, and the type of steel needed for your application. Failing to verify these details can lead to functional issues down the line, including insufficient strength or corrosion resistance, ultimately resulting in project delays and increased costs.

Another frequent oversight occurs during the selection of suppliers. Relying solely on the lowest price can be tempting, but it often leads to compromising on quality. It's essential to evaluate potential suppliers based on their reputation, product quality, and customer service. Engaging with experienced suppliers can provide valuable insights into material choices, fabrication processes, and industry standards that will help ensure the reliability and longevity of the pipes and fittings you select for your project.

Related Posts

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

2025 Top 10 Advantages of Using Mild Steel Pipes for Construction

-

2025 How to Choose the Right 304 Stainless Steel Pipe for Your Project

-

Top 10 Benefits of Using 304 Stainless Steel Pipe in Modern Construction

-

How to Choose the Right 2205 Duplex Stainless Steel for Your Project Based on Mechanical Properties and Corrosion Resistance

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil