How to Choose Stainless Steel 316L for Your Projects?

Choosing the right material for your projects is crucial. Stainless steel 316L stands out in various industries. Its corrosion resistance and durability are vital for applications in marine environments and chemical processing. According to a 2022 market research report, the demand for stainless steel 316L increased by 15% annually, reflecting its growing importance.

Experts advocate for careful consideration when selecting stainless steel 316L. John Silver, a materials engineer, once stated, "Understanding the specific needs of your project guides the choice of stainless steel 316L." This highlights the need for project-specific assessment. Many professionals overlook nuances, leading to suboptimal outcomes.

Recognizing imperfections in decisions can improve future selections. For example, understanding the differences between standard stainless steel and stainless steel 316L can prevent costly mistakes. Awareness of its unique properties is essential for success in demanding conditions. Focus on what truly matters ensures better project results.

Understanding Stainless Steel 316L: Properties and Benefits

Stainless steel 316L is a low-carbon version of 316 stainless steel, designed for specific applications. Its properties include excellent corrosion resistance, making it ideal for marine and chemical environments. According to industry reports, this alloy's molybdenum content increases its resistance to pitting corrosion, which is crucial for underwater applications.

One of the main benefits of 316L is its toughness at high temperatures. It maintains strength in extreme conditions, with a tensile strength of about 70,000 psi. However, choosing the right stainless steel necessitates consideration of its limitations. For instance, while 316L is highly resistant to oxidation, it can still corrode under certain environments. Appropriate surface treatment is essential to enhance its longevity.

In structural applications, weldability is significant. 316L is easy to weld, but improper techniques can reduce its durability. Overheating can lead to issues like sensitization. The importance of proper preparation and technique cannot be overstated. Balancing the material's advantages with its potential drawbacks maximizes your project's success.

Identifying Applications Suitable for Stainless Steel 316L

Stainless steel 316L is known for its excellent corrosion resistance. It's a well-suited material for many applications. This alloy features low carbon content, which enhances its resistance to pitting and crevice corrosion. It's particularly ideal for marine environments where saltwater and humidity are prevalent.

Common applications of 316L include chemical processing equipment, medical devices, and aerospace components. In the chemical industry, its resistance to corrosive substances makes it a preferred choice. In medical applications, its biocompatibility ensures safety for implants and surgical instruments. It's also used in architecture for its aesthetic appeal and durability.

**Tip:** Always evaluate your project requirements carefully. Consider environmental factors like temperature and chemical exposure.

While 316L is versatile, it is not the only option. Assessing alternatives may yield surprising results. Some projects may benefit from lower-cost materials.

**Tip:** Look into the specific conditions your application will face. Even a slight change can affect performance and longevity. Choosing the right material is essential for success.

How to Choose Stainless Steel 316L for Your Projects? - Identifying Applications Suitable for Stainless Steel 316L

| Application Area | Reason for Use | Industry Examples |

|---|---|---|

| Marine Environments | Excellent corrosion resistance in saltwater. | Shipbuilding, Offshore drilling platforms |

| Medical Applications | High cleanliness and corrosion resistance required. | Surgical instruments, Medical implants |

| Food Processing | Resistant to rust and easy to clean. | Food equipment, Dairy processing plants |

| Chemical Processing | Resistant to various corrosive chemicals. | Pharmaceuticals, Petrochemicals |

| Architecture & Construction | Durability and aesthetic appeal. | Facades, Handrails |

Factors to Consider When Selecting Stainless Steel 316L

Choosing stainless steel 316L for your projects involves several important factors. One key aspect is corrosion resistance. According to the ASTM A240 report, 316L stainless steel contains a higher percentage of molybdenum, which enhances its resistance to pitting in chloride environments. This is particularly critical for marine applications.

Another factor is mechanical strength. 316L maintains its strength even at elevated temperatures. A study by the International Stainless Steel Forum highlights that it performs well up to 870°C. However, it’s necessary to consider the environment. If your project involves extreme temperatures or heavy loads, other alloys might be more suitable.

Cost is also a concern. 316L stainless steel generally costs more than other stainless steels. It is essential to balance your budget with performance needs. Sometimes, opting for a less expensive alternative can lead to compromised durability. Do thorough research before making a choice. Reflect on whether the benefits justify the cost.

Comparing Stainless Steel 316L with Other Grades

When selecting materials for projects, it’s crucial to compare stainless steel grades. Stainless steel 316L stands out due to its excellent corrosion resistance. This grade contains molybdenum, which enhances its resilience against chlorides, making it ideal for marine environments. Reports indicate that 316L has a corrosion rate of less than 0.1 mm/year in seawater, while lower grades can suffer far more.

In contrast, stainless steel 304 is a more common choice but lacks the same level of protection. While 304 offers decent corrosion resistance, it can corrode more quickly in saline conditions. It's essential to realize that using the wrong type may lead to early project failure. Data shows that projects often face increased maintenance costs when lower-grade materials are used in harsh environments.

However, 316L is not without challenges. Its fabrication can be more demanding due to its lower workability compared to 304. Also, it carries a higher price tag, which can affect overall project budgets. Sometimes, the benefits of using 316L might not justify the cost. Careful evaluation is necessary to ensure it meets specific project needs while balancing budget constraints.

Stainless Steel Grades Comparison

This bar chart compares the corrosion resistance ratings of different stainless steel grades, highlighting how Stainless Steel 316L stands out with a rating of 9 out of 10, making it an excellent choice for projects requiring high resistance to corrosion.

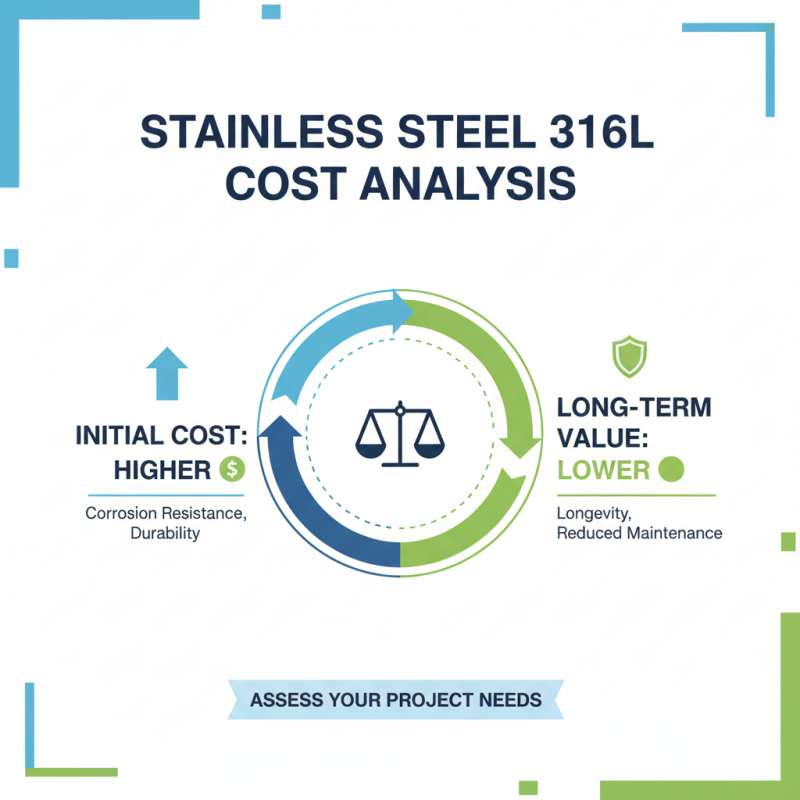

Cost Analysis and Sourcing Recommendations for Stainless Steel 316L

When considering Stainless Steel 316L for your projects, a detailed cost analysis is essential. 316L is known for its corrosion resistance and durability. However, these benefits come with a price. The initial cost may be higher than other materials. Nevertheless, its longevity can justify the expense in the long term. Carefully assess your specific needs to ensure you choose wisely.

Sourcing recommendations play a crucial role in managing costs. Look for suppliers with a solid reputation. Compare prices and evaluate quality. Local suppliers may offer quicker delivery. However, consider international suppliers for competitive pricing. You might find better deals, but shipping could add extra costs. Always factor this into your budget.

Tips for sourcing: be upfront about your requirements. Discuss your project with suppliers. This can lead to bulk discounts. Don’t shy away from negotiating. Understand the material specifications to avoid potential issues later. Small details matter. Ensure you get what you pay for; quality should never be compromised. Keep a close eye on your budget and project expectations.

Related Posts

-

Top 10 Benefits of Using Stainless Steel 316L in Your Projects

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

-

Why Choose Duplex Stainless Steel for Your Next Project and Its Advantages

-

How to Choose the Right Seamless Steel Pipe for Your Project Needs

-

How to Choose the Right Inconel Pipe for Your Project Needs

-

Top Stainless Fittings Types for Your Next Project?

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil