How to Choose the Right 4 Inch Steel Pipe for Your Project

Choosing the right materials is critical in construction. The "4 inch steel pipe" plays a vital role in various projects. Expert Mark Thompson, a structural engineer, emphasizes, "Selecting the right steel pipe can make or break your project."

When considering a "4 inch steel pipe," factors like thickness, length, and application matter. These pipes can support heavy loads. They can resist corrosion, but not all pipes are created equal. Some may not perform well under pressure. It's essential to evaluate the specific needs of your project carefully.

Understanding the different grades of steel is also important. Not every "4 inch steel pipe" will fit your requirements. A lack of research could lead to costly mistakes. Ensure you consult with manufacturers or experienced professionals. Quality should never be compromised for a lower price. Each decision affects the overall success of the project.

Understanding the Basics of 4 Inch Steel Pipes and Their Applications

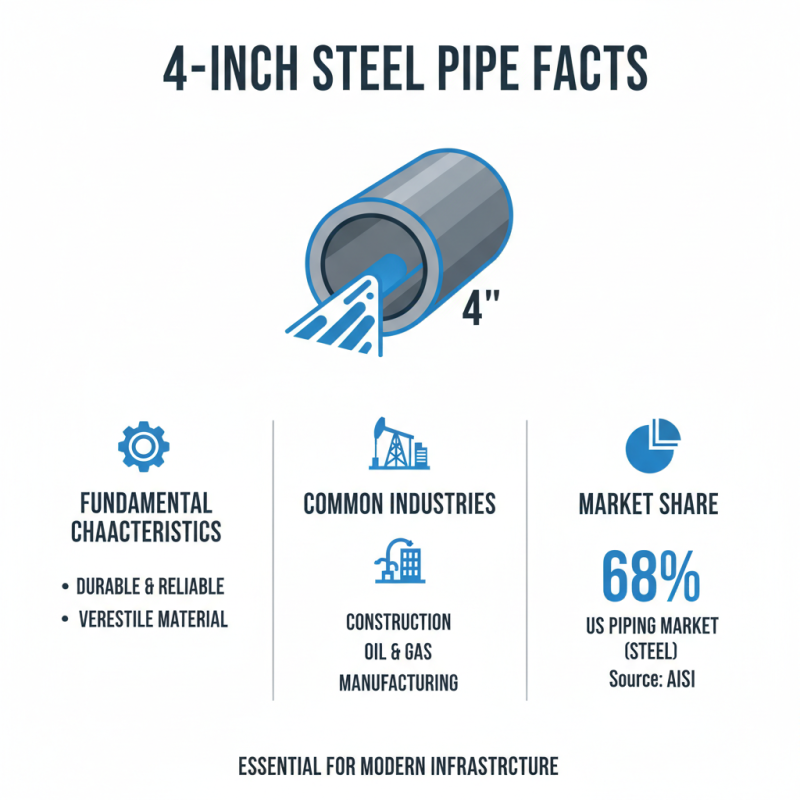

When selecting a 4-inch steel pipe, understanding its fundamental characteristics is essential. These pipes are commonly used in various industries, such as construction and oil and gas. According to the American Iron and Steel Institute, steel pipes account for around 68% of the total piping market in the U.S. This statistic illustrates the material's significance.

The applications of 4-inch steel pipes vary widely. In water transportation, they can handle significant pressure, making them a popular choice. A report by the International Energy Agency indicates that infrastructure projects increasingly rely on these pipes for their durability. However, miscalculating the required thickness can lead to failures. It's a mistake that can be costly.

Additionally, understanding the different types of steel grades is crucial. Not all grades offer the same corrosion resistance or strength. The ASTM A53 grade, for instance, is often preferred for structural applications. Yet, some projects may need a more corrosion-resistant type. This decision can significantly influence the project's success.

Evaluating the Different Types of 4 Inch Steel Pipes Available in the Market

When selecting a 4-inch steel pipe, it’s crucial to consider its intended use. Various types of steel pipes exist, catering to different applications. For instance, structural steel pipes are great for construction. They provide strength and durability. However, they may not perform well in corrosive environments.

Another option is galvanized steel pipes. These pipes resist rust due to their protective zinc coating. This characteristic makes them suitable for plumbing and HVAC systems. However, if the coating wears down over time, the underlying steel can corrode.

Welded steel pipes offer another avenue to explore. They feature seams along their length. These pipes can be less expensive but may have lower pressure ratings. It's important to evaluate these qualities based on your project’s specific requirements. Not all pipes are created equal, and making informed choices can prevent costly mistakes down the line.

Factors to Consider When Selecting a 4 Inch Steel Pipe for Your Project

Choosing the right 4-inch steel pipe requires careful consideration of various factors. Start by assessing the intended use of the pipe. Is it for structural support or fluid transport? Each application demands different properties. For instance, pipes used in construction must endure high stress. Pipes for fluids need to resist corrosion and leaks.

Next, think about the environment where the pipe will be installed. Does it face extreme temperatures or moisture? These conditions can impact the pipe’s lifespan. Selecting a pipe that can withstand specific environmental factors is crucial. Thickness and material grade also play significant roles in durability and safety.

Finally, consider the budget without compromising quality. Cheaper options may lead to long-term costs from maintenance. Sometimes, projects overlook the importance of proper installation. Poor installation can cause issues down the line, affecting the project’s integrity. Make sure to reflect on these aspects carefully before making a decision.

Assessing the Quality and Standards of 4 Inch Steel Pipes

When selecting a 4-inch steel pipe, assessing quality and standards is crucial. Look for pipes made from reliable materials. Check for certifications that indicate compliance with industry standards. Not all suppliers provide this information upfront, so you may need to ask. A trusted source should offer transparency about their product quality.

Tip: Always inspect the pipe for visible defects, such as rust or weld issues. Small imperfections can lead to larger problems later on. If you're uncertain about what to look for, consider consulting an expert or doing more research.

Another important factor is the pipe's thickness. Standard gauges can vary, affecting the pipe's durability and performance. Sometimes, a thicker wall provides better longevity but also increases cost. Balance quality and budget to find the right fit for your project.

Tip: Request samples when available. It's a tangible way to examine the quality firsthand. Always be ready to reassess your options. Not every choice will be ideal, and that’s part of the process.

Installation and Maintenance Tips for 4 Inch Steel Pipes in Projects

When installing 4-inch steel pipes, attention to detail matters. Proper installation can prevent future costly repairs. According to a report by the American Society of Mechanical Engineers (ASME), improperly installed pipes can lead to leaks or structural failures. This highlights the importance of following best practices during installation.

Ensure all joints are tightly sealed. Use quality fittings that match the pipe's specifications. Regular maintenance checks are vital, too. Surveys show that routine inspections can reduce operational failures by 30%. Look for signs of rust or corrosion, which can compromise the pipe's integrity over time.

Users should be aware of environmental factors. Steel pipes may react to extreme temperatures or humidity. Regularly clean the exterior to avoid buildup. A neglected pipe may not fail immediately, but issues can become severe without attention. Create a schedule for maintenance and stick to it. This helps in identifying potential problems early and can save money in the long run.

Installation and Maintenance Tips for 4 Inch Steel Pipes

Related Posts

-

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

-

Top 10 Benefits of Using 304 Stainless Steel Pipe in Modern Construction

-

How to Choose the Best 2 Inch Stainless Steel Pipe for Your Project

-

2025 Top 10 Advantages of Using Mild Steel Pipes for Construction

-

2025 How to Choose the Right 304 Stainless Steel Pipe for Your Project

-

Why Hot Rolled Coil is Essential for Construction and Manufacturing Industries

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil