2026 Best Stainless Steel Tube Fittings for Your Projects?

In the world of construction and engineering, choosing the right materials is crucial. Among these, stainless steel tube fittings have gained immense popularity. They are durable and resistant to corrosion, making them ideal for various applications. However, not all stainless steel tube fittings are created equal.

When sourcing the best fittings for your projects, you might feel overwhelmed by the options. From different shapes to sizes, there are many factors to consider. Each project has unique requirements that can complicate the selection process. Some fittings may look appealing but fail to meet performance standards.

Understanding the properties of stainless steel tube fittings can lead to better choices. Look for quality certifications and customer reviews. These aspects can help you avoid costly mistakes. While the perfect fitting may seem elusive, thorough research is essential. Your projects deserve the best, and reliable fittings play a significant role in that success.

Understanding Stainless Steel Tube Fittings: An Overview

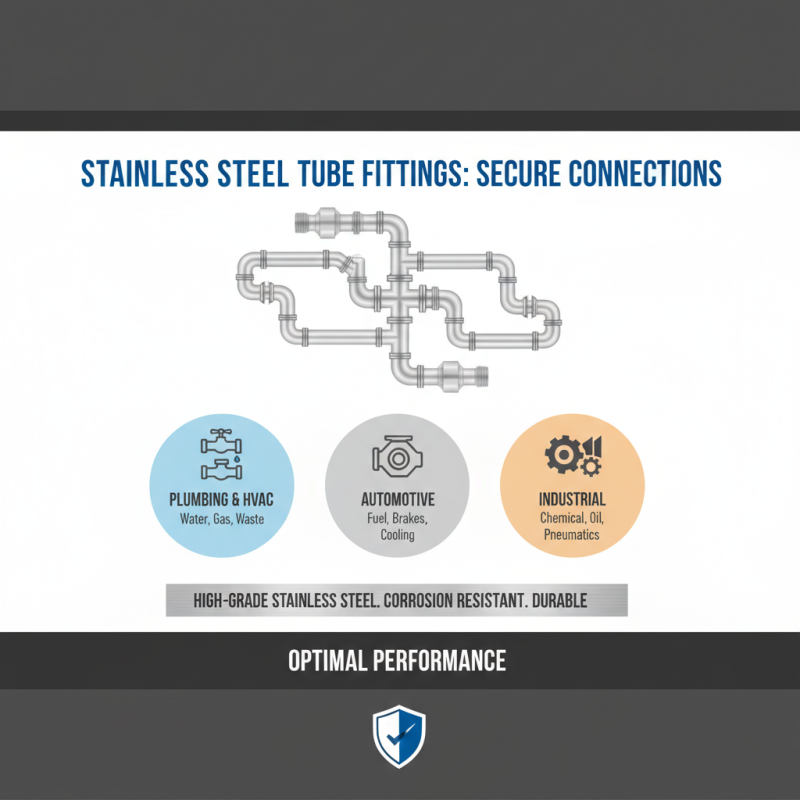

Stainless steel tube fittings play a crucial role in various projects. They are essential in creating secure connections in plumbing, automotive, and industrial applications. Often made from high-grade stainless steel, these fittings resist corrosion and maintain structural integrity over time. Choosing the right fitting is critical for optimal performance.

Many people overlook the importance of proper sizing and compatibility. A mismatched fitting can lead to leaks or failures. It's vital to understand specifications, such as diameter and pressure ratings. Educating yourself on these details can save time and resources in the long run.

Additionally, the installation process deserves attention. A simple mistake during installation might result in costly repairs later. Using the appropriate tools and techniques is paramount. Even seasoned professionals can benefit from double-checking their work. Reflecting on past experiences helps avoid repeated errors in current projects.

Key Features to Look for in Stainless Steel Tube Fittings

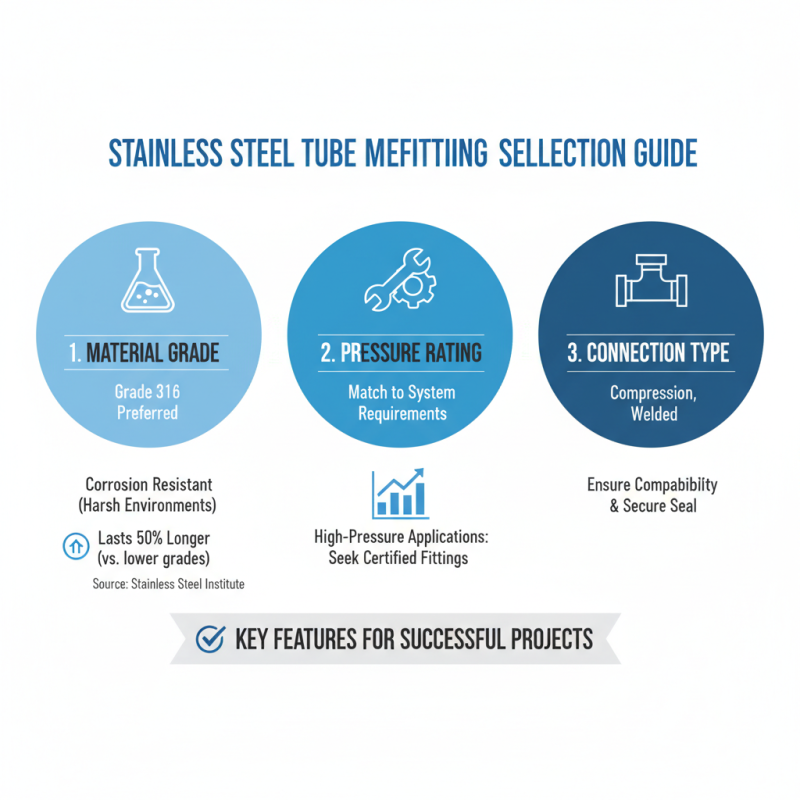

When selecting stainless steel tube fittings, several key features are critical for successful projects. Firstly, consider the material grade. Generally, grade 316 stainless steel is preferred for most applications due to its resistance to corrosion, especially in harsh environments. A study by the Stainless Steel Institute reveals that components made from this grade can last up to 50% longer than those made from lower-grade materials.

The fitting design should accommodate your specific needs. Look for options that offer a variety of sizes and connections. A well-designed fitting can improve flow rates, reducing potential pressure drops. Interestingly, more than 30% of failures in piping systems can be attributed to poor fitting choices, according to recent industry reports.

Sealing and installation reliability are also essential features. Fittings that require complex installations may lead to mistakes. It’s imperative to choose products that come with clear guidelines and support. This can save time and reduce failure rates, which are as high as 20% in improperly installed systems. When evaluating options, ensure you’re weighing these features against potential drawbacks in your specific application.

Top Brands of Stainless Steel Tube Fittings for 2026

When selecting stainless steel tube fittings for your projects in 2026, consider various top brands well-known for their quality. Each brand offers unique features that cater to different applications. Some may focus on corrosion resistance, while others prioritize pressure handling or temperature tolerance. Assess your project needs before making a decision.

Tips: Always check material certifications. This ensures the fittings meet industry standards. Moreover, understand the fittings' specifications. They can impact assembly and overall performance.

Some brands may dominate the market, but don't overlook smaller companies. They often provide innovative solutions and custom options. You might discover a fitting that better suits your specific needs. However, be cautious; not all products from lesser-known brands have undergone rigorous testing.

In the end, it's essential to evaluate the fit and compatibility of the fittings. Measure your tubes accurately. A poor fit can lead to leaks or failures, jeopardizing your project. Always inspect the construction quality for durability, even if it looks fine at first glance.

Comparison of Price Ranges for Stainless Steel Tube Fittings

When choosing stainless steel tube fittings, understanding price ranges is crucial. The prices can vary significantly depending on the type, material grade, and finish. Recent industry reports indicate that basic stainless steel fittings start around $0.50 each. In contrast, specialized fittings can exceed $100. This broad spectrum highlights the importance of project requirements.

Mid-range fittings, often found between $1 and $50, offer a balance of quality and affordability. Various sources, including the American Society of Mechanical Engineers, suggest that investing in higher-quality fittings may reduce long-term maintenance costs. Low-quality fittings might save money upfront but may lead to leaks or failures later.

In addition, the demand for stainless steel fittings is rising. Research shows a projected growth rate of 5% annually over the next few years. This might increase prices as manufacturers respond to market dynamics. Keep in mind, choosing the right fitting is a blend of cost and performance. It demands careful evaluation and reflection on what fits your project's needs best.

Common Applications of Stainless Steel Tube Fittings in Various Industries

Stainless steel tube fittings are essential in many industries. In construction, they connect pipes and tubing, ensuring smooth fluid flow. The durability of these fittings is crucial. They resist corrosion and can withstand high pressures. This makes them suitable for heating and cooling systems.

In the pharmaceutical industry, cleanliness is paramount. Stainless steel fittings help maintain sterile conditions. They prevent contamination in sensitive processes. This is vital for product safety. However, their installation requires precision. A small mistake can lead to leaks or failures. Regular inspection is necessary to avoid costly issues.

Food processing also benefits from stainless steel fittings. They ensure safe transportation of liquids. Their ability to withstand harsh cleaning agents is key. Yet, it's easy to overlook maintenance. Neglecting this can affect product quality. Proper training for staff is crucial to reduce these risks. Overall, while stainless steel fittings offer many advantages, attention to detail is necessary to maximize their performance.

Related Posts

-

Top SS Pipe Fittings Guide for Ultimate Performance and Durability

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

-

2026 Top Steel Pipe Fittings Types You Need to Know?

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

-

Top Stainless Fittings Types for Your Next Project?

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil