2026 Best Stainless Steel Pipe Options for Your Projects?

The selection of the right stainless steel pipe is crucial for any project. Stainless steel pipes are known for their durability and resistance to rust. They come in various types and grades, making choices overwhelming at times. Project managers must consider factors like thickness, diameter, and application.

In 2026, several stainless steel pipe options stand out. Each option serves different industrial needs. The wrong choice can lead to costly mistakes and project delays. Identifying key features and specifications is essential to make informed decisions.

Some might overlook the importance of surface finish. A well-finished pipe can enhance performance and longevity. Users often find it challenging to compare options without guidance. This article aims to clarify the best stainless steel pipe choices available in 2026. By exploring various options, we help you avoid common pitfalls and choose wisely.

2026 Overview of Stainless Steel Pipe Materials and Grades

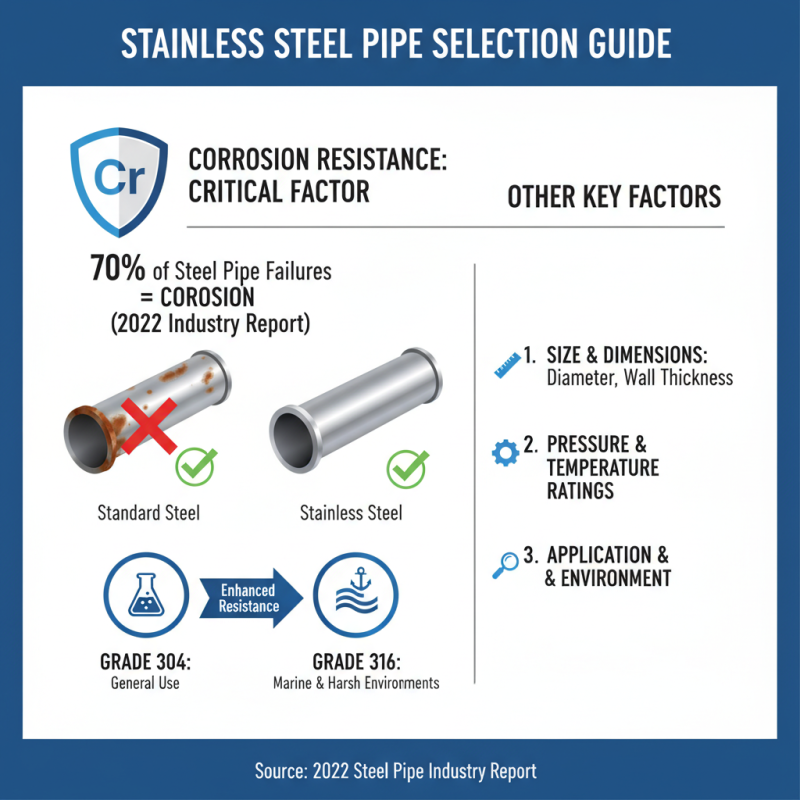

When selecting stainless steel pipes for projects, understanding materials and grades is crucial. Stainless steel is primarily chosen for its corrosion resistance and durability. The American Iron and Steel Institute (AISI) categorizes stainless steel into various grades, including 304, 316, and 321. Each grade has specific properties suited for different applications. For example, grade 304 offers excellent corrosion resistance in mildly corrosive environments.

Grade 316 includes molybdenum, enhancing chloride resistance, making it ideal for marine applications. Choosing the right grade can significantly impact the project’s long-term performance. However, the cost factor cannot be ignored. Higher grades generally cost more due to the additional alloying elements.

Industry reports indicate that using lower-grade stainless steel can lead to premature failure in harsh environments. A 2020 report highlighted that around 30% of projects faced issues from improper material selection. This statistic shows a need for better education on stainless steel properties. Understanding these nuances allows for informed decisions that can save time and money in the long run.

2026 Best Stainless Steel Pipe Options

Factors to Consider When Choosing Stainless Steel Pipes

When selecting stainless steel pipes, several factors demand attention. Corrosion resistance is a key attribute. According to a 2022 industry report, around 70% of steel pipe failures are due to corrosion. This highlights the importance of choosing a grade suitable for your application. For instance, types 304 and 316 offer different levels of corrosion resistance, with 316 being more effective in marine environments.

The pipe's intended use is also vital. High-pressure systems require thicker walls. In contrast, low-pressure systems may perform well with standard thickness. An API study noted that improper wall thickness can lead to a 40% increase in failure rates. Additionally, consider the environment. Extreme temperatures or chemical exposure can affect the pipe's longevity. Choose a material that fits the project's unique demands.

Cost is another consideration. While cheaper options may seem attractive, they can lead to higher maintenance costs. A 2023 analysis indicated that projects using high-quality materials saved up to 30% on long-term maintenance. Thus, investing in the right stainless steel pipe can yield substantial savings. Making a hurried decision based solely on upfront costs can backfire. Balancing quality with budget is essential for a successful outcome.

Top Stainless Steel Pipe Manufacturers to Consider in 2026

When selecting stainless steel pipes for your projects in 2026, understanding the landscape of top manufacturers is essential. Industry reports suggest that demand for stainless steel pipes has surged, driven by construction and energy sectors. In 2022, the stainless steel pipe market reached approximately $15 billion, and it is expected to grow at a CAGR of 5% from 2023 to 2028.

Key players in the market have invested heavily in innovation. They focus on corrosion resistance and strength. However, not every manufacturer meets these standards consistently. Some suppliers struggle with quality control, which can lead to project delays and increased costs. A survey indicated that nearly 30% of construction professionals have faced quality issues with pipes, emphasizing the need for diligent evaluation.

Sustainability also plays a significant role in selecting manufacturers. Firms that prioritize eco-friendly practices are gaining traction. More companies are pushing for recycled materials in production. But, not every manufacturer adheres to these principles. It's crucial to verify their claims. This insight helps ensure you work with responsible entities.

Applications and Uses of Stainless Steel Pipes in Various Industries

Stainless steel pipes are versatile. They serve many industries, from construction to food processing. In construction, they provide strength and durability. They resist rust and corrosion, ensuring long-term use. These pipes are ideal for plumbing and structural applications.

In the automotive sector, stainless steel pipes are used for exhaust systems. They enhance performance and reduce emissions. The food industry benefits too. Stainless steel pipes maintain hygiene and resist bacterial growth. They are essential in conveying liquids and gases safely.

Tips: Always consider the environment when selecting pipes. The correct material can save costs in the long run. Regular maintenance is crucial. Even durable stainless steel can suffer from improper handling. Be mindful of how pipes are installed. Poor installation can lead to leaks or failures. Consider long-term needs before purchasing.

2026 Best Stainless Steel Pipe Options for Your Projects

| Pipe Type | Diameter (inches) | Wall Thickness (mm) | Applications | Corrosion Resistance |

|---|---|---|---|---|

| Seamless Pipes | 1 - 12 | 1.5 - 10 | Oil & Gas, Chemical Processing | Excellent |

| Welded Pipes | 0.5 - 30 | 0.5 - 12 | Construction, Plumbing | Good |

| Square & Rectangular Pipes | 2x2 - 12x12 | 2 - 10 | Structural Applications | Moderate |

| Fluid Conduits | 1 - 10 | 1 - 5 | Food Processing, Beverage Industry | Excellent |

| High-Pressure Pipes | 1 - 8 | 2 - 12 | Power Generation, Marine Applications | Very Good |

Maintenance and Care Tips for Stainless Steel Pipes in Projects

Maintaining stainless steel pipes is essential for longevity. Simple care can make a big difference. Regular inspection is crucial to detect any signs of wear. Look for rust spots or discoloration. These can signal deeper issues.

Cleaning the pipes should be routine. Use a soft cloth and mild detergent for regular cleaning. Avoid abrasive materials that can scratch the surface. Sometimes, despite our best efforts, issues arise. Corrosion can occur in certain environments, like those with high salt content. It’s important to assess these risks based on project location.

Proper installation is also vital. Ensure that pipes are fitted properly to prevent leaks. Leaks can lead to further damage over time. Regularly check joints and connections. Use appropriate seals to enhance longevity. Overall, paying attention to these details can help maintain stainless steel pipes effectively. Neglect can lead to problems down the line.

Related Posts

-

Top 10 Benefits of Using 304 Stainless Steel Pipe in Modern Construction

-

How to Choose the Best 2 Inch Stainless Steel Pipe for Your Project

-

Why Steel Pipe Fittings Are Essential for Your Plumbing Projects

-

2025 Top Duplex Stainless Steel Innovations for Enhanced Performance and Durability

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

-

How to Choose the Right Seamless Steel Pipe for Your Project Needs

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil