Top Benefits of Using Carbon Steel Pipe in Construction and Industry

The use of carbon steel pipe in construction and industry has gained significant attention due to its remarkable properties and versatility. Carbon steel pipes are known for their high tensile strength and durability, making them ideal for a wide range of applications, from structural frameworks to pipelines in various industrial sectors. This introduction explores the key benefits of incorporating carbon steel pipe into construction projects, highlighting its cost-effectiveness, resistance to wear and corrosion, and adaptability to different environments.

One of the standout advantages of carbon steel pipe is its ability to withstand high pressures and extreme temperatures, which is crucial for many industrial applications. Additionally, the ease of fabrication and welding of carbon steel allows for smoother installation processes, reducing labor costs and project timelines. The material is also readily available, contributing to a consistent supply chain, which is a vital aspect for any construction project aiming for efficiency and timeliness.

Moreover, the sustainability of carbon steel is noteworthy; it is highly recyclable and can be repurposed at the end of its lifecycle, making it an environmentally friendly option. As industries continue to evolve and seek efficient solutions, the use of carbon steel pipe presents a compelling case, combining performance, economy, and sustainability in one reliable material.

Overview of Carbon Steel Pipe and Its Uses

Carbon steel pipe is a versatile piping material that is widely used in various sectors such as construction, oil and gas, and manufacturing. Its composition, primarily consisting of iron and carbon, provides excellent strength and durability, making it suitable for high-pressure and high-temperature applications. The inherent toughness of carbon steel allows it to withstand harsh environmental conditions, which is crucial for infrastructure projects and industrial operations.

In construction, carbon steel pipes are often utilized for structural purposes, such as in the framework of buildings and bridges. They can also be found in plumbing and heating systems due to their ability to handle hot water and steam effectively. The availability of carbon steel pipes in multiple grades and sizes allows engineers and contractors to select the appropriate type based on specific project requirements. Additionally, their cost-effectiveness compared to other materials further enhances their appeal, making them a popular choice in both commercial and residential construction.

In industrial applications, carbon steel pipes are essential for transporting fluids and gases, contributing to efficient operations in sectors like energy and manufacturing. Their high resistance to wear and tear, combined with the ability to be fabricated into various shapes and sizes, makes them ideal for complex piping systems. This adaptability, along with easy maintenance and longevity, underscores the significance of carbon steel pipes in driving productivity and safety across industries.

Advantages of Carbon Steel Pipe in Construction

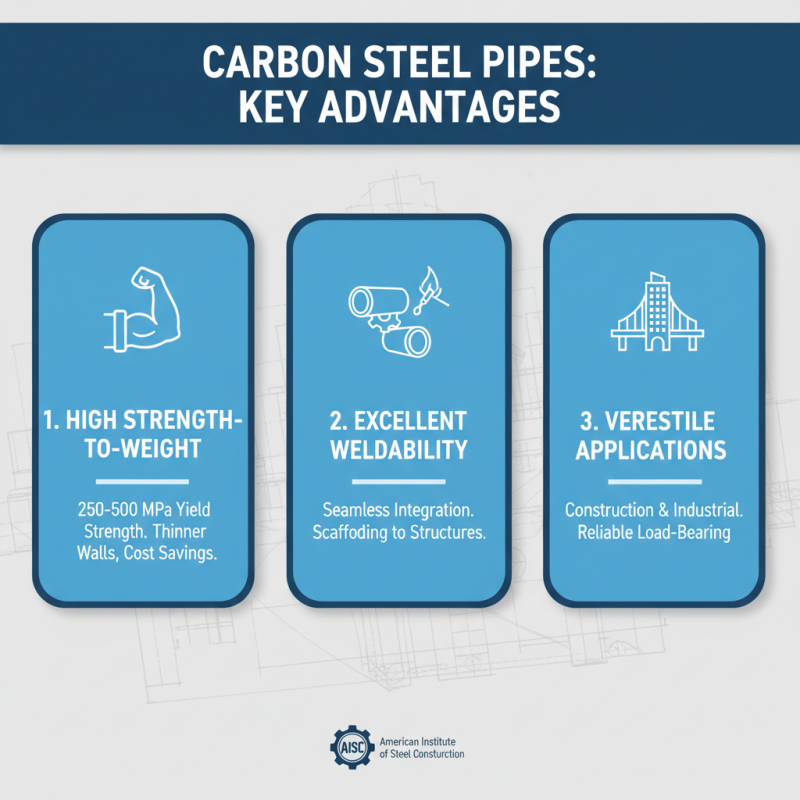

Carbon steel pipes have become a staple in construction and industrial applications due to their numerous advantages. One notable benefit is their exceptional strength-to-weight ratio. According to the American Institute of Steel Construction (AISC), carbon steel's yield strength can range from 250 to 500 MPa, making it ideal for load-bearing structures. This high strength allows for the implementation of thinner walls, reducing material costs, while still maintaining structural integrity. Moreover, carbon steel pipes exhibit excellent weldability, which enables seamless integration into diverse construction projects, from scaffolding to structural frameworks.

In addition to strength, carbon steel pipes are also known for their durability and corrosion resistance when properly treated. The Steel Construction Institute reports that with appropriate coatings or galvanization, carbon steel can withstand harsh environmental conditions and extend the lifespan of infrastructure. Their low thermal expansion coefficient also translates to stability under varying temperature conditions, a crucial factor in construction where temperature fluctuations can lead to structural stress. These characteristics make carbon steel pipes a reliable choice for both temporary and permanent installations, ensuring safety and longevity in construction practices.

Benefits of Carbon Steel Pipe in Industrial Applications

Carbon steel pipes have established themselves as a cornerstone in various industrial applications due to their remarkable mechanical properties and cost-effectiveness. According to a report by the World Steel Association, carbon steel accounts for approximately 75% of all steel production globally, highlighting its widespread use across sectors such as construction, oil and gas, and manufacturing. The material is lauded for its strength and durability, enabling it to withstand high pressures and harsh environments, which is essential in applications like pipeline transport and structural components.

Moreover, the versatility of carbon steel pipes is a significant advantage in industrial settings. They can be easily fabricated into various shapes and sizes, allowing for customization in different projects. According to market research conducted by Grand View Research, the global carbon steel pipe market size was valued at USD 70 billion in 2022, with expectations for substantial growth driven by infrastructure development and energy projects. Enhanced weldability and malleability are key characteristics that facilitate efficient installation and maintenance, making carbon steel pipes a preferred choice for engineers and project managers.

With their ability to handle extreme temperatures and corrosive environments, carbon steel pipes continue to play a vital role in supporting the industrial landscape.

Comparison of Carbon Steel Pipe with Other Materials

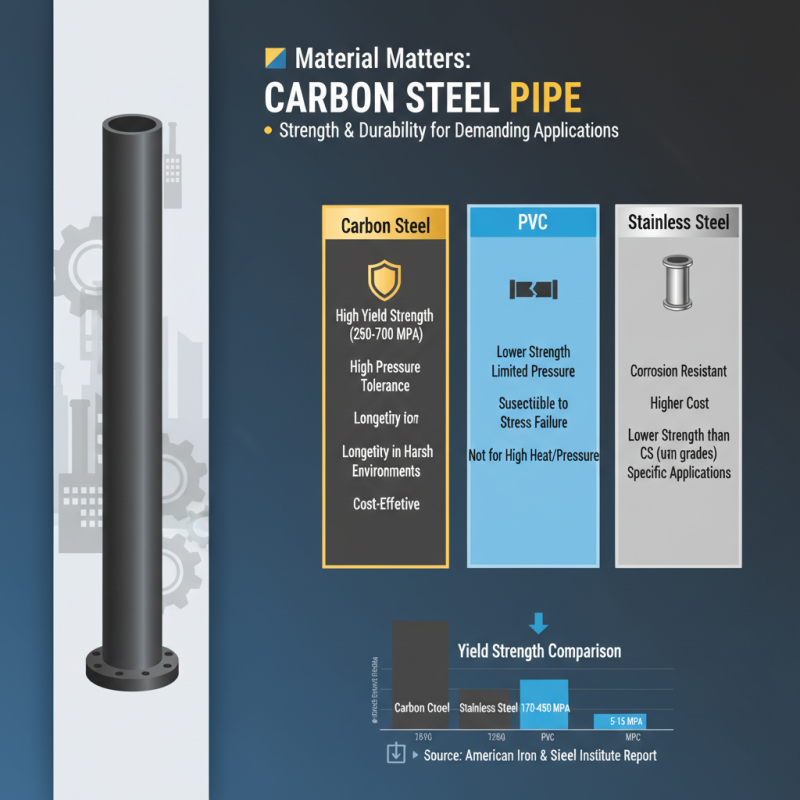

When evaluating materials for construction and industrial applications, carbon steel pipe stands out due to its unique properties that distinguish it from alternatives like PVC and stainless steel. According to a report by the American Iron and Steel Institute, carbon steel pipes exhibit a high yield strength, typically ranging from 250 to 700 MPa, making them suitable for high-pressure applications. This strength ensures durability and a longer lifespan in demanding environments, where lighter materials such as PVC can fail under stress.

In contrast, while stainless steel offers excellent corrosion resistance, it comes at a significantly higher cost—often 2 to 3 times that of carbon steel. The World Steel Association states that the global demand for carbon steel continues to rise, primarily due to its cost-effectiveness and reliable performance. Additionally, carbon steel pipes are easily weldable, allowing for seamless integration into existing structures, which can be a challenging process with more rigid materials. Thus, for many construction projects, the choice between carbon steel and other materials ultimately hinges on a balance of strength, cost, and ease of installation, favoring carbon steel in numerous applications.

Future Trends in Carbon Steel Pipe Usage in Industry

The use of carbon steel pipes in various industries is on the rise, driven by their exceptional strength, durability, and cost-effectiveness. As industries evolve, the demand for carbon steel pipes is expected to increase significantly. According to a report from MarketsandMarkets, the global carbon steel pipe market is projected to reach USD 117.82 billion by 2026, growing at a CAGR of 4.4% from 2021. This growth is largely attributed to the increasing construction activities and infrastructure development across emerging economies.

One of the notable future trends is the integration of advanced technologies such as automation and IoT (Internet of Things) in manufacturing processes. These innovations aim to enhance the quality assurance of carbon steel pipes while reducing production costs. Additionally, the growing emphasis on sustainability is driving industries to adopt practices that focus on recycling and using environmentally friendly materials. Research from the Global Steel Innovation Forum indicates that the shift towards low-carbon manufacturing processes could further boost the appeal of carbon steel pipes, ensuring their viability in a market that increasingly values sustainability.

Furthermore, the energy sector, particularly in oil and gas, is expected to remain a significant market for carbon steel pipes. The International Energy Agency (IEA) has forecasted a steady rise in global energy demand, leading to increased investments in pipeline infrastructure. With the ongoing advancements in corrosion resistance and the ability to withstand extreme conditions, carbon steel pipes are poised to play a critical role in meeting future energy demands while ensuring efficient transport and reduced environmental impact.

Top Benefits of Using Carbon Steel Pipe in Construction and Industry - Future Trends in Carbon Steel Pipe Usage in Industry

| Dimension | Application | Benefits | Future Trends |

|---|---|---|---|

| 3" x 0.250" | Oil and Gas | High pressure resistance | Increased adoption in upstream activities |

| 6" x 0.500" | Construction | Durability and mechanical strength | Smart manufacturing techniques |

| 4" x 0.375" | Water Supply | Corrosion resistance | Eco-friendly production processes |

| 2" x 0.250" | Manufacturing | Cost-effectiveness | Increased automation in production |

| 5" x 0.450" | Structural Applications | Versatility and adaptability | Sustainable materials utilization |

Related Posts

-

2025 How to Choose the Right 304 Stainless Steel Pipe for Your Project

-

2025 Top 10 Inconel Pipe Applications for Industrial Excellence

-

How to Choose the Right Stainless Steel Tube for Your Project Needs

-

2025 Top 10 Advantages of Using Mild Steel Pipes for Construction

-

10 Essential Tips for Choosing the Right Mild Steel Pipe for Your Project

-

How to Choose the Right 2205 Duplex Stainless Steel for Your Project Based on Mechanical Properties and Corrosion Resistance

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil