Why Choose Duplex Stainless Steel for Your Next Project and Its Advantages

In the ever-evolving landscape of materials science, duplex stainless steel has emerged as a material of choice for various industries due to its remarkable properties. As Dr. John Smith, a renowned expert in metallurgy, aptly stated, “Duplex stainless steel combines the best of both worlds—the strength of ferritic steel and the corrosion resistance of austenitic steel.” This unique blend not only enhances durability but also ensures longevity in challenging environments.

The advantages of duplex stainless steel extend beyond its mechanical strength. Its impressive resistance to pitting and stress corrosion cracking positions it as an ideal candidate for projects where reliability is paramount. Additionally, the lesser amount of nickel used in its composition makes it a cost-effective option in comparison to traditional stainless steels, especially vital in large-scale projects. As industries continue to seek sustainable and long-lasting solutions, duplex stainless steel stands out, promising to meet the demands of modern engineering and construction challenges effectively.

By choosing duplex stainless steel for your next project, you’re not just investing in a material; you’re investing in a future of innovation and sustainability, ensuring that the structures and systems you create can withstand the test of time.

What is Duplex Stainless Steel and Its Composition?

Duplex stainless steel is a unique blend of austenitic and ferritic stainless steel, typically composed of around 22% chromium, 5% nickel, and significant amounts of molybdenum. This composition results in a metallic structure that combines the advantageous properties of both types of stainless steel, providing high strength and excellent corrosion resistance. The dual-phase microstructure enhances its performance under stress and makes it particularly suitable for high-pressure environments.

When considering duplex stainless steel for your project, it is essential to understand its remarkable mechanical properties. Its higher yield strength allows for thinner designs, leading to weight and material savings. Additionally, its resistance to localized corrosion forms, such as pitting and crevice corrosion, makes it ideal for industries like oil and gas, chemical processing, and marine applications.

**Tip:** Ensure that the duplex stainless steel you choose has undergone proper testing to meet specific standards for your application’s requirements, as variations in composition can significantly affect performance.

Moreover, duplex stainless steel offers excellent weldability and can be used in challenging fabrication processes, which can further enhance your project’s feasibility. When sourcing materials, remember to consult with your supplier about the specific grades and their suitability for your intended use.

**Tip:** Always consider future maintenance; duplex stainless steel can significantly reduce maintenance needs over its lifespan when compared to other steels, making it a cost-effective choice in the long run.

Key Advantages of Duplex Stainless Steel in Corrosion Resistance

Duplex stainless steel is gaining traction in various industries due to its superior corrosion resistance, particularly in harsh environments. According to a report by the International Stainless Steel Forum (ISSF), duplex stainless steels have a unique microstructure that consists of a mixture of austenite and ferrite phases, which provides enhanced resistance to pitting and crevice corrosion. This remarkable characteristic makes duplex stainless steel an ideal choice for applications in the oil and gas industry, marine environments, and chemical processing, where exposure to aggressive media is common.

The corrosion resistance of duplex stainless steel is quantified by its PREN (Pitting Resistance Equivalent Number) value, which often exceeds that of conventional stainless steels. For instance, duplex grades typically possess a PREN value of 30 or higher, compared to austenitic grades that typically range from 20 to 25. This heightened resistance allows structures and components made from duplex stainless steel to not only resist the damaging effects of chlorides but also to reduce maintenance and replacement costs over time. Furthermore, the longevity of products made from duplex stainless steel contributes to overall sustainability in engineering practices, as they require fewer resources for upkeep and replacement, aligning with the industry’s push for more sustainable materials.

Advantages of Duplex Stainless Steel in Corrosion Resistance

This chart illustrates the corrosion resistance ratings of duplex stainless steel across various categories. Duplex stainless steel is highly regarded for its superior resistance to pitting, stress corrosion cracking, and crevice corrosion, making it an excellent choice for projects requiring durability in harsh environments.

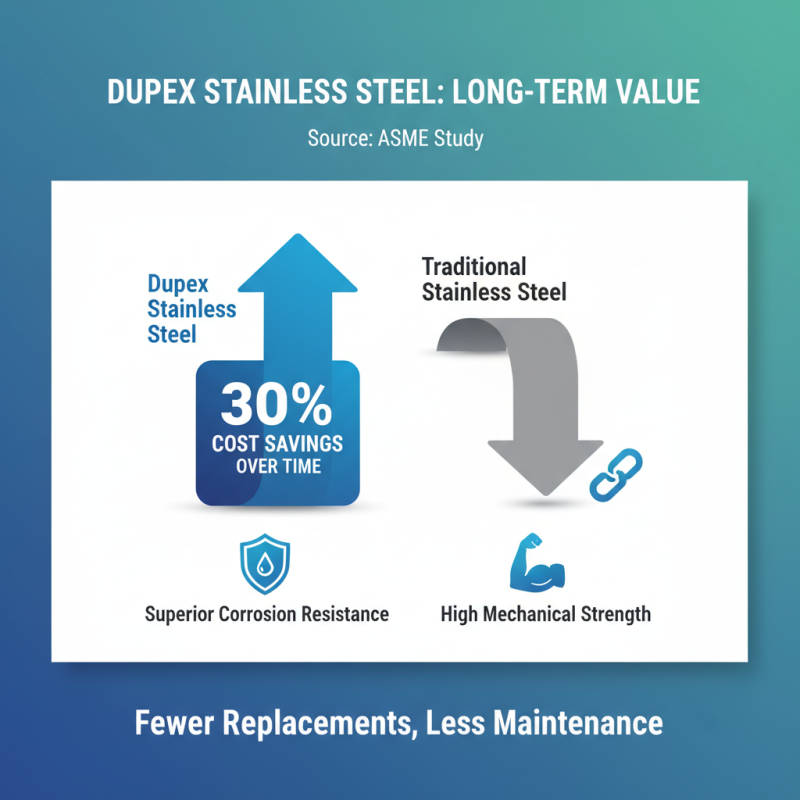

Cost-Effectiveness of Duplex Stainless Steel Over Time

Duplex stainless steel has gained popularity in various industries due to its outstanding cost-effectiveness over time. A study by the American Society of Mechanical Engineers (ASME) highlights that duplex stainless steel can offer life-cycle cost savings of up to 30% compared to traditional austenitic stainless steels, primarily due to its superior corrosion resistance and mechanical strength. This means that projects using duplex materials often require fewer replacements and less maintenance, translating to lower long-term expenses.

Additionally, the unique microstructure of duplex stainless steel not only enhances its durability but also allows for thinner sections without compromising strength. According to a report from the International Stainless Steel Forum (ISSF), projects that used duplex stainless steel reported 20-40% weight savings, which can significantly reduce transport and installation costs. This material's resilience makes it an ideal choice for harsh environments, which may otherwise require frequent repairs and reinforcements.

**Tips:** When considering duplex stainless steel, review past projects to gauge their long-term performance and cost savings. Ensure your suppliers can provide comprehensive documentation of material properties. Regular maintenance schedules can further extend the lifespan of developments using duplex stainless steel, maximizing your investment.

Applications of Duplex Stainless Steel in Various Industries

Duplex stainless steel is increasingly being utilized across various industries due to its unique properties, particularly its high strength and excellent resistance to corrosion. In the oil and gas sector, duplex stainless steel is preferred for its ability to withstand harsh environments, including high pressures and aggressive media. According to a report by Grand View Research, the global duplex stainless steel market is projected to witness a CAGR of over 5% from 2021 to 2028, driven largely by this industry's demand for durable materials.

In the chemical processing industry, duplex stainless steel is widely used in the construction of reactors, heat exchangers, and piping systems. Its remarkable resistance to pitting, crevice corrosion, and stress corrosion cracking makes it an ideal choice for chemical reactions that involve chlorides. The ASTM standards specify various duplex grades, highlighting their suitability in applications where safety and longevity are paramount.

Tips: When considering duplex stainless steel for your next project, it's essential to evaluate the specific environmental conditions the material will face. Conducting a thorough material compatibility analysis can help in selecting the right grade, ensuring optimal performance and lifespan. Additionally, collaborating with experienced professionals in the field will provide valuable insights into the best practices for fabrication and installation.

Why Choose Duplex Stainless Steel for Your Next Project and Its Advantages - Applications of Duplex Stainless Steel in Various Industries

| Industry | Applications | Advantages |

|---|---|---|

| Oil & Gas | Piping, valves, and flanges | High resistance to chloride stress corrosion cracking |

| Chemical Processing | Storage tanks, reactors, and heat exchangers | Superior corrosion resistance and mechanical strength |

| Marine | Shipbuilding, offshore platforms | Excellent resistance to seawater corrosion |

| Food Processing | Food storage and processing equipment | Easily cleaned and maintains hygiene standards |

| Power Generation | Heat exchangers, gas turbines | High temperature strength and resistance |

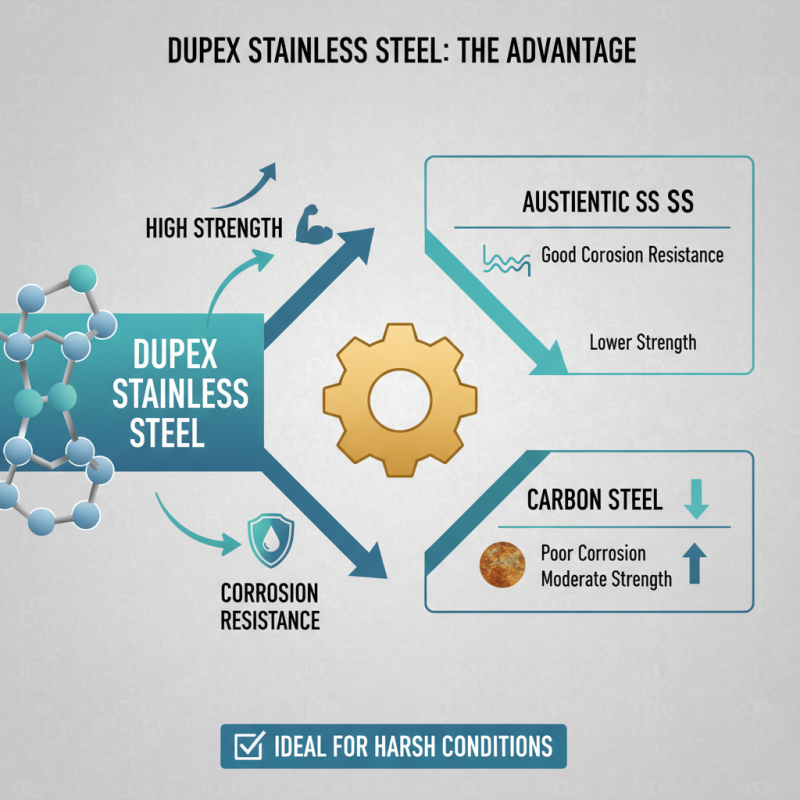

Comparison of Duplex Stainless Steel with Other Materials

Duplex stainless steel is increasingly favored in various industries due to its unique properties, particularly when compared to other materials such as austenitic stainless steel and carbon steel. One of the primary advantages of duplex stainless steel is its excellent combination of strength and corrosion resistance. While austenitic stainless steel offers good corrosion resistance, it typically has lower strength. In contrast, duplex stainless steel provides higher yield strength, making it a suitable choice for applications requiring structural integrity under harsh conditions.

When pitted against carbon steel, duplex stainless steel showcases superior resistance to corrosion, especially in environments prone to chloride exposure. Carbon steel, while strong, is prone to rust and corrosion when exposed to moisture and chemicals. This vulnerability can lead to higher maintenance costs and more frequent replacements. Additionally, duplex stainless steel can handle higher temperatures and pressures, making it ideal for applications in the oil and gas industry, marine environments, and chemical processing. The durability and long lifespan of duplex stainless steel ultimately make it a more economical choice in the long term, reducing the need for frequent repairs or replacements.

Related Posts

-

2025 Top Duplex Stainless Steel Innovations for Enhanced Performance and Durability

-

How to Choose the Right Duplex Stainless Steel for Your Industrial Applications

-

2025 Top 10 Applications of Duplex Stainless Steel in Modern Industries

-

Top 10 Tips for Working with 2205 Duplex Stainless Steel Applications

-

How to Choose the Right 2205 Duplex Stainless Steel for Your Project Based on Mechanical Properties and Corrosion Resistance

-

How to Choose the Best 2 Inch Stainless Steel Pipe for Your Project

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by nvisage

Português do Brasil

Português do Brasil